This device is type A, so it is not necessary its connection to an outside exhaust conduit.

However, the device must be installed under a cooker extractor to ensure complete removal of

gases from the combustion.

LOCATION

-

The gas cooking table top must be installed in a well-ventilated place according to current

regulations, and

it’s not designed for fitted kitchen.

-

It must have sufficient ventilation to prevent the formation of unacceptable concentrations of

products detrimental to health.

-

The walls adjacent to the kitchen appliances must be able to bear increases in temperature

of 65

C.

-

This appliance must not be placed on or against surfaces made of inflammable or

combustible material. It must be kept at a minimum distance of 300 mm from the walls.

-

It is important to ensure that the cooker is in a levelled position to ensure its stability.

-

Before connecting the gas, the plastic film protecting the outer surface must be

removed.

GAS CONNECTION

-

Connect gas in compliance with current safety regulation. The appliances are prepared for

connection according to Norms ISO-7 or ISO 228-1.

-

The general installation of gas shall be provided with a gas shut-off valve (stopcock). It is

advisable to have a gas shut-off valve for each appliance in order not to leave unused the

entire installation in the event of failure of any of the equipment in service.

-

After consulting the data plate, check that the cooker is being fed with the right type of gas

and pressure.

-

Ensure that there is no flame, near by, and also that all the gas valves controls are in the

closed position.

-

The gas collector has an outlet gas pressure, if necessary, measure the pressure of the gas

as close as possible to the injectors.

-

Once you have connected the gas on, check to ensure that all the connections are tights. To

do this, use a solution of water and soap. DO NOT USE A FLAME TO CHECK GAS LEAKS.

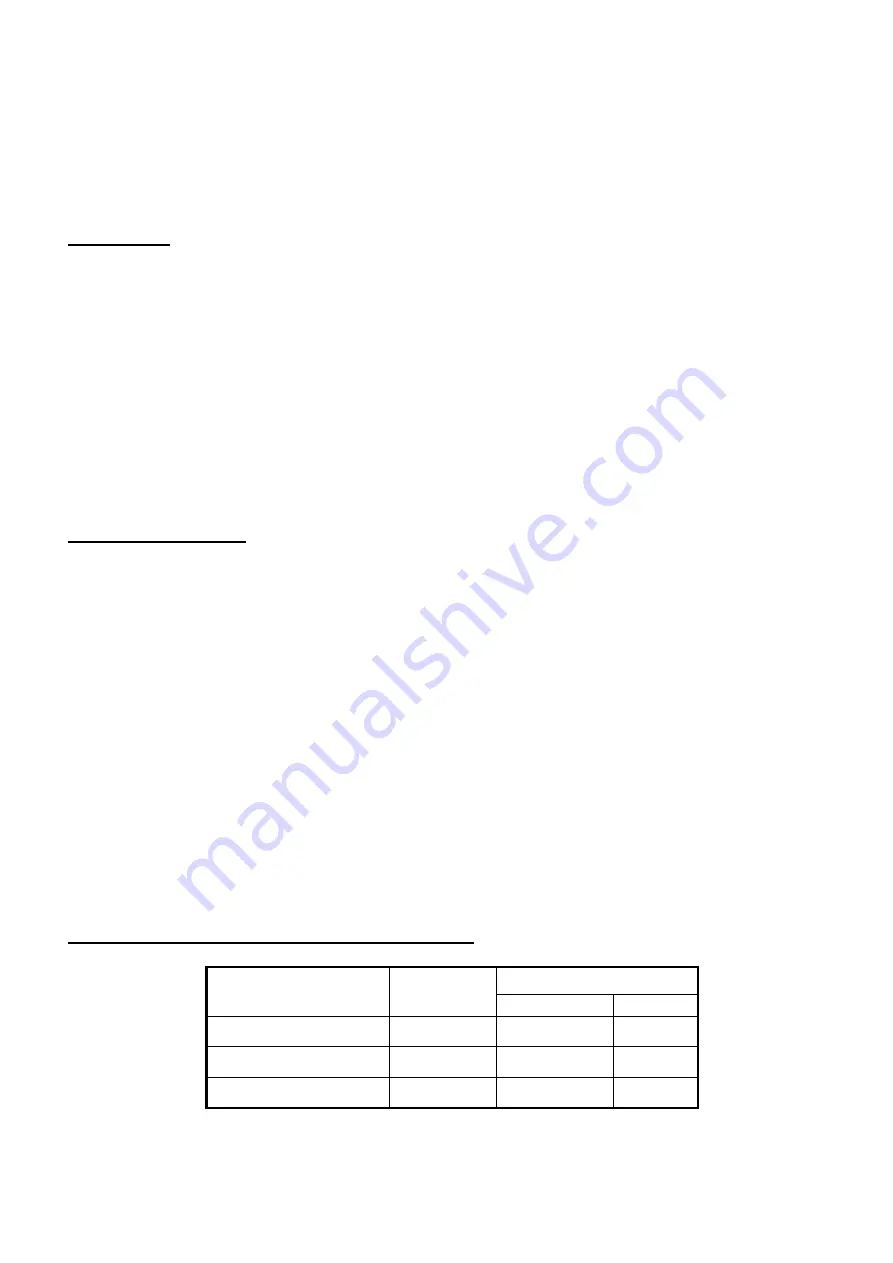

OPERATING PRESSURES AND INJECTORS

Gas

Pressure

Burner / Injectors (

mm)

2750

3400

G20 (Natural Gas)

20 mbar

115

125

G30 (Butane Gas)

28-30 mbar

85

93

G31 (Propane Gas)

37 mbar

85

93

The power of the burners was determined on the basis of the net calorific value of the gas.