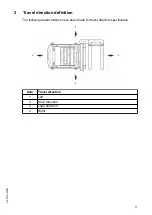

3.2

Assembly Overview

5

6

7

11

9

8

20

22

21

15

17

16

18

25

26,27

28

30

31

41

29

42

33

40

38

36

36

37

39

34

35

13

13

14

12

10

24

23

19

32

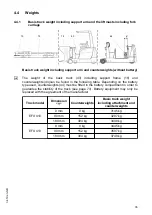

Item

Description

5

t

Steering wheel

6

t

Control panel and driver's display

7

t

"Hydraulic functions" control lever

8

t

Key switch

9

t

Emergency disconnect switch

10

t

Operator position

11

t

Overhead guard

12

o

Strobe light or warning beacon

13

o

Laser-beam rack-compartment display

14

o

Working lights

15

t

Lift mast

16

o

Rear-view mirror (left- and right-hand)

17

t

Handles

18

t

Load handler

19

t

Fork carriage

20

t

Dead man's switch

21

t

Brake pedal

24

04.19 en-GB

Summary of Contents for EFX 410

Page 1: ...EFX 410 413 03 13 Operating instructions 51296679 04 19 en GB EFX 410 EFX 413 ...

Page 2: ...2 ...

Page 4: ...4 04 19 en GB ...

Page 12: ...0506 GB 2 0506 GB 2 ...

Page 72: ...70 04 19 en GB ...

Page 90: ...88 04 19 en GB ...

Page 250: ...248 04 19 en GB ...

Page 261: ...The Operator specific settings menu now opens 259 04 19 en GB ...

Page 376: ......

Page 380: ...02 16 EN 6 ...

Page 382: ...02 16 EN 8 14 Safety instructions and warning information ...

Page 404: ......