F 5

0903

.GB

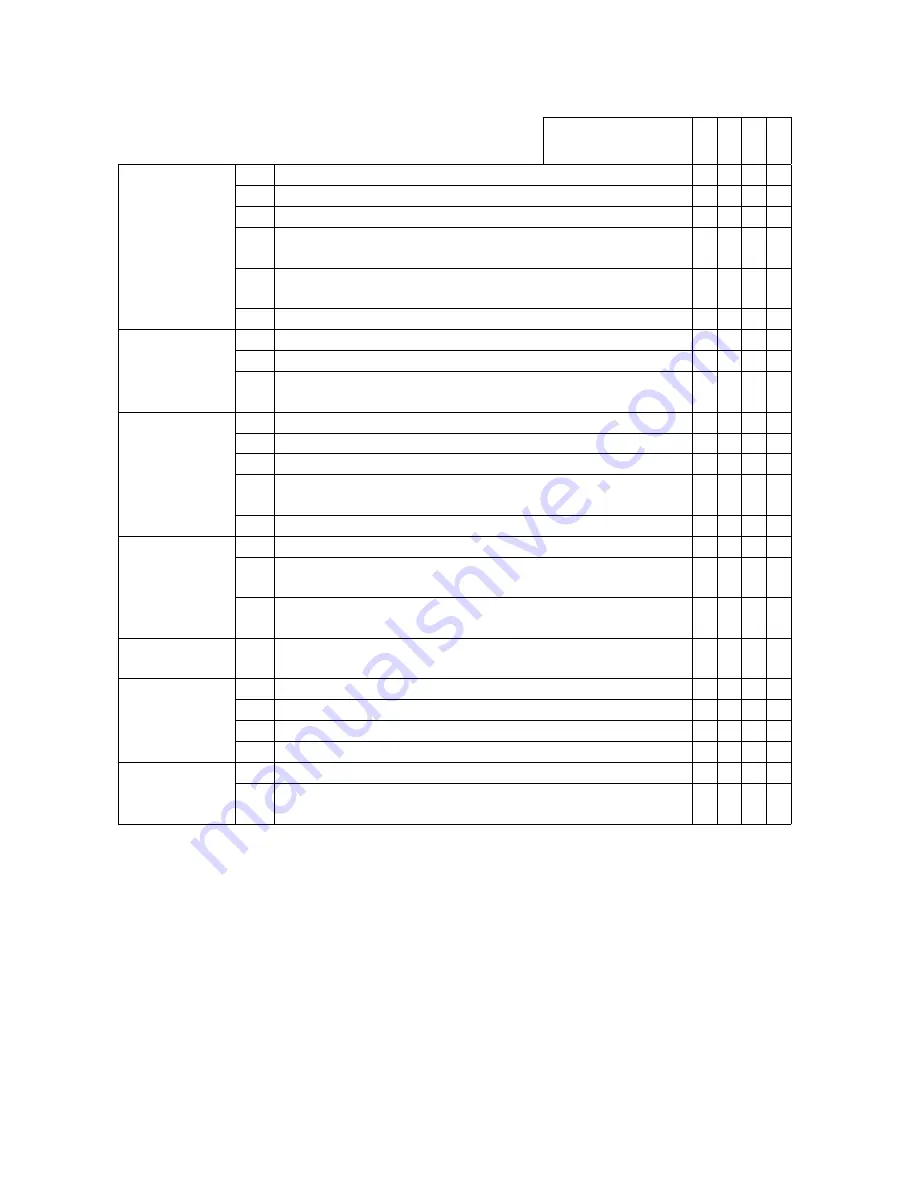

Maintenance intervals

Standard

=

t

W M M M

Cold store

=

k

1 3 6 12

Electric

system:

7.1 Function check

t

7.2 Check cables for secure connection and damage

t

7.3 Check fuses for correct amperage

t

7.4 Check switches and switch cams for secure seat and

proper function

t

7.5 Check the warning facilities and safety circuits for proper

function

k t

7.6 Check contactors, replace wearing parts if necessary

t

Electric

motors:

8.1 Check carbon brush wear

t

8.2 Check the motor for secure attachment

t

8.3 Clean motor housing with a vacuum cleaner, check

commutator for wear

k t

Battery:

9.1 Check acid density, acid level, and cell voltage

l t

9.2 Check terminals for secure attachment and apply grease

l t

9.3 Clean battery plug connections, check for tight seat

l t

9.4 Check battery cables for damage and replace, if

necessary

t

9.5 Ckec the battery lock

t

Lifting

device:

10.1 Check performance, wear and adjustment

t

10.2 Perform sight check of rollers, sliding elements, and

stops

l t

10.3 Check fork arms and fork arm carriage for wear and

damage

l t

Lubrication:

11.1 Grease the truck in accordance with the lubrication

schedule

l t

General

measurements:

12.1 Check the electrical system for a grounding fault

t

12.2 Check travel speed and braking distance

t

12.3 Check lifting and lowering speed

t

12.4 Check safety facilities and cut-off devices

t

Demonstra-

tion:

13.1 Perform trial run under nominal load

t

13.2 Upon completion of servicing operations, demonstrate

the truck to the person responsible

l t

F 5

0903

.GB

Maintenance intervals

Standard

=

t

W M M M

Cold store

=

k

1 3 6 12

Electric

system:

7.1 Function check

t

7.2 Check cables for secure connection and damage

t

7.3 Check fuses for correct amperage

t

7.4 Check switches and switch cams for secure seat and

proper function

t

7.5 Check the warning facilities and safety circuits for proper

function

k t

7.6 Check contactors, replace wearing parts if necessary

t

Electric

motors:

8.1 Check carbon brush wear

t

8.2 Check the motor for secure attachment

t

8.3 Clean motor housing with a vacuum cleaner, check

commutator for wear

k t

Battery:

9.1 Check acid density, acid level, and cell voltage

l t

9.2 Check terminals for secure attachment and apply grease

l t

9.3 Clean battery plug connections, check for tight seat

l t

9.4 Check battery cables for damage and replace, if

necessary

t

9.5 Ckec the battery lock

t

Lifting

device:

10.1 Check performance, wear and adjustment

t

10.2 Perform sight check of rollers, sliding elements, and

stops

l t

10.3 Check fork arms and fork arm carriage for wear and

damage

l t

Lubrication:

11.1 Grease the truck in accordance with the lubrication

schedule

l t

General

measurements:

12.1 Check the electrical system for a grounding fault

t

12.2 Check travel speed and braking distance

t

12.3 Check lifting and lowering speed

t

12.4 Check safety facilities and cut-off devices

t

Demonstra-

tion:

13.1 Perform trial run under nominal load

t

13.2 Upon completion of servicing operations, demonstrate

the truck to the person responsible

l t

Summary of Contents for EKE 30-2 ac

Page 1: ...Operating instructions 50272276 EKE 30 2 ac G 08 02 09 03...

Page 3: ...0108 GB...

Page 7: ...0600 GB A 2...

Page 23: ...1002 GB D 6...

Page 26: ...E 3 0903 GB 1 2 17 18 12 13 14 19 15 16 3 4 5 6 7 8 9 10 11 20...

Page 37: ...0903 GB E 14...