G 13

0

708

.USA

6.3

Inspecting the lift chains

Impermissible wear and external damage:

According to official regulations, a chain is worn when it has lengthened by 3% in the

area where it runs over the deflection pulley. We recommend replacing the chain at

2% for safety reasons.

The chain should be replace immediately in the event of any external damage,

because such damage eventually causes permanent breaks.

IMPORTANT

If the industrial truck is equipped with two lift chains, both chains must always

be replaced. This is the only way to ensure that the load is distributed evenly

on both chains. When chains are replaced, the connection bolts between the

chain anchor and the chain must also be replaced. Use only new original

parts.

6.4

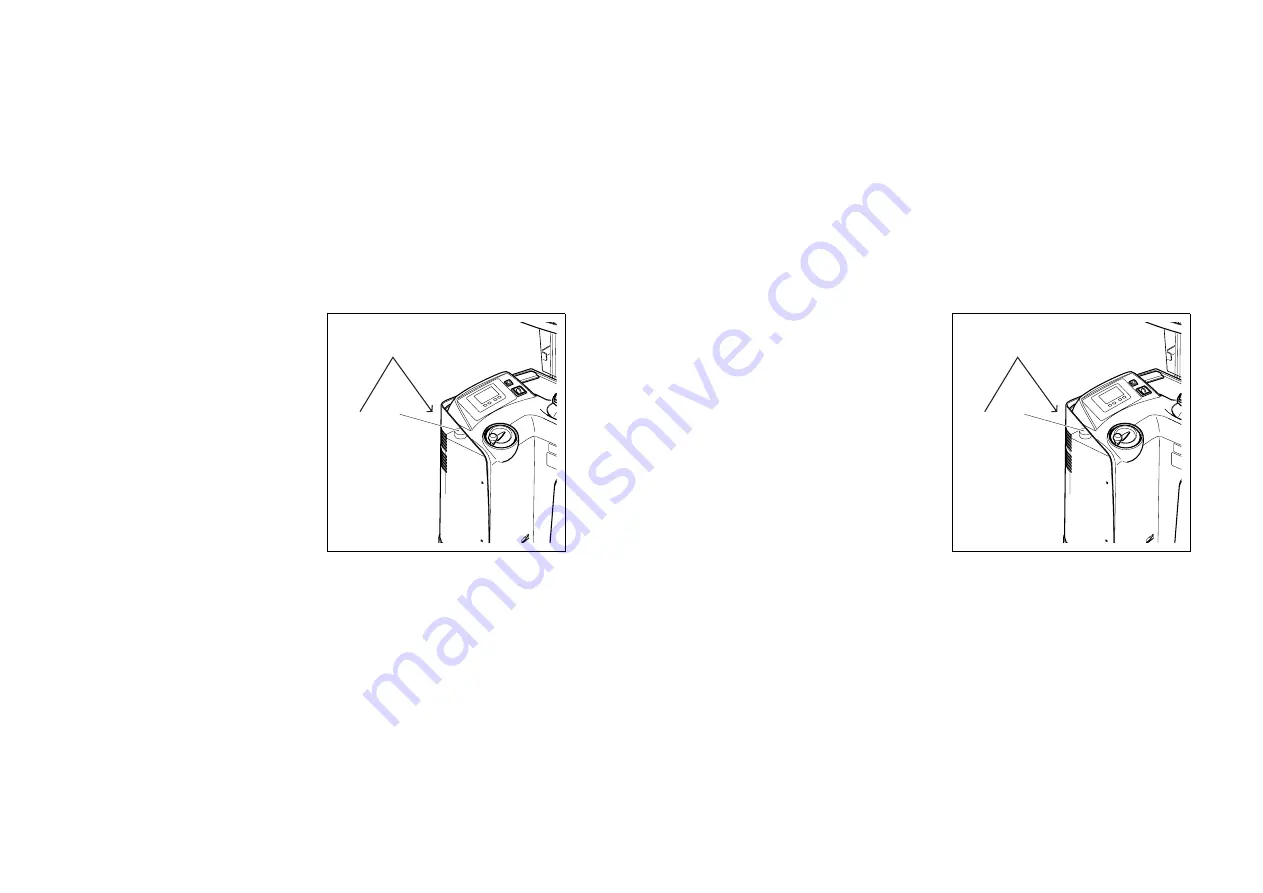

Checking the hydraulic oil level

– Open the door to the engine compartment.

– Preparing the industrial truck for

maintenance and servicing

(see section 6).

– Check the hydraulic fluid level in the

hydraulic tank on the side on the level

indicator (3).

NOTICE

The load carrier must be

completely lowered to read the

fluid level on the hydraulic tank.

– If needed, add hydraulic fluid of the

correct specification into the filler neck

(2) (hydraulic fluid specification,

see section 5).

2

3

G 13

0

708

.USA

6.3

Inspecting the lift chains

Impermissible wear and external damage:

According to official regulations, a chain is worn when it has lengthened by 3% in the

area where it runs over the deflection pulley. We recommend replacing the chain at

2% for safety reasons.

The chain should be replace immediately in the event of any external damage,

because such damage eventually causes permanent breaks.

IMPORTANT

If the industrial truck is equipped with two lift chains, both chains must always

be replaced. This is the only way to ensure that the load is distributed evenly

on both chains. When chains are replaced, the connection bolts between the

chain anchor and the chain must also be replaced. Use only new original

parts.

6.4

Checking the hydraulic oil level

– Open the door to the engine compartment.

– Preparing the industrial truck for

maintenance and servicing

(see section 6).

– Check the hydraulic fluid level in the

hydraulic tank on the side on the level

indicator (3).

NOTICE

The load carrier must be

completely lowered to read the

fluid level on the hydraulic tank.

– If needed, add hydraulic fluid of the

correct specification into the filler neck

(2) (hydraulic fluid specification,

see section 5).

2

3

Summary of Contents for ETR 314

Page 1: ...Operating instructions 50 452 907 ETR 314 320 u 06 06 11 09 07 08 E Manual de instrucciones...

Page 7: ...0608 USA I 4 0608 USA I 4...

Page 9: ...0606 USA A 2 0606 USA A 2...

Page 24: ...D 9 0107 USA D 9 0107 USA...

Page 26: ...D 11 0107 USA D 11 0107 USA...

Page 103: ...0107 USA F 10 0107 USA F 10...

Page 123: ...0708 USA G 20 0708 USA G 20...

Page 135: ...0608 E I 4 0608 E I 4...

Page 137: ...0606 E A 2 0606 E A 2...

Page 152: ...D 9 0107 E D 9 0107 E...

Page 154: ...D 11 0107 E D 11 0107 E...

Page 225: ...0608 E E 66 0608 E E 66...

Page 235: ...0107 E F 10 0107 E F 10...

Page 255: ...0708 E G 20 0708 E G 20...