E

XTRAORDINARY MAINTENANCE MANUAL

-

CT

R

EV

.

01

20-05-2016

16 / 20

Jurop

SpA

Via Crosera n° 50

33082 Azzano Decimo, PN (Italia)

T

EL

.

+39

0434

636811

F

AX

.

+39

0434

636812

http://www.jurop.it

e-mail: info@jurop.it

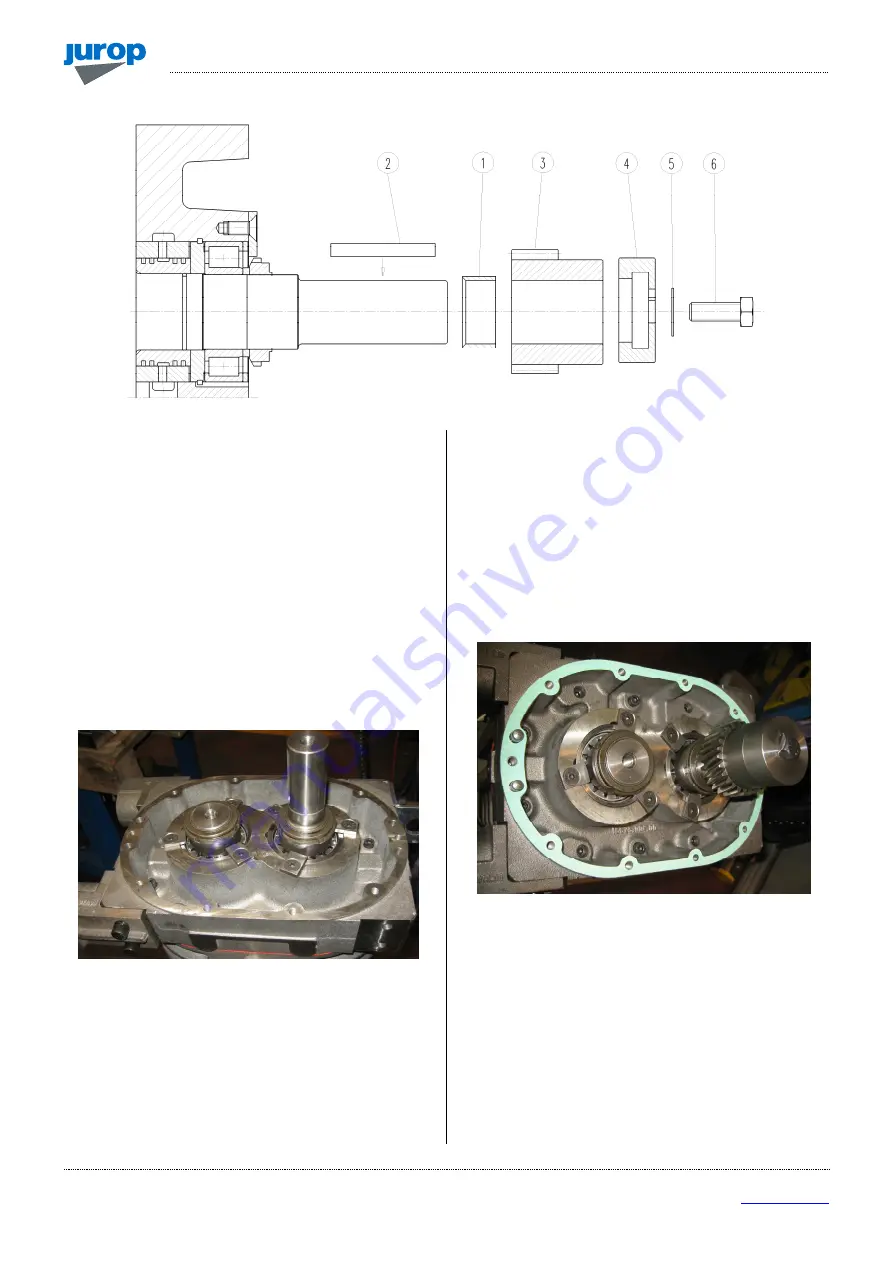

Assembling of the gear overdrive unit

Fig. 5.22

• The gear overdrive unit is installed as an alternative to the front

carter.

• Mount the spacer having thickness of 18mm instead of the

splashing oil disc unit in the lower shaft.

• Insert no. 4 pins Ø10x30 in the front bench and mount the related

gasket.

• Mount the overdrive driven gear components in the following

order:

-

Spacer (1).

-

Tab (2).

-

Overdrive drived gear (3).

-

Spacer (4).

-

Safety washer (5).

-

Screw M12 (6).

• Bend the safety washer to block the screw rotation.

Fig. 5.23

• Mount the overdrive housing careful centering the guiding pins.

• Tighten the screws M8 (10 pcs) with the relative grower washers

fixing the overdrive housing to the bench.

• Mount the rear bearing (22207 E/C3) of the overdrive driving shaft:

-

Oil the bearing seat.

-

Insert the bearing using the tool no. 7.

• Oil the internal ring of the bearing and mount the overdrive driving

shaft.

• Insert no. 4 Ø10x20 pins in the overdrive housing and mount the

relative gasket.

• Mount the front overdrive cover with bearing support.

• Tighten the screws M8 (10 pcs) with the relative grower washer

fixing the front overdrive cover.

• Mount the front bearing (21309 E/C3) of the overdrive driving

shaft:

-

Oil the bearing seat.

-

Insert the bearing using the tool no°7.

Fig. 5.24