REV

.

11

30-05-2017

INSTALLATION

,

USE AND MAINTENANCE MANUAL

JULIA 3000-5000-7000-8000-8500-9000

-

HP

23 / 51

Jurop

SpA

Via Crosera n° 50

33082 Azzano Decimo, PN (Italy)

T

EL

.

+39

0434

636811

F

AX

.

+39

0434

636812

http://www.jurop.it

e-mail: info@jurop.it

Attention:

Carefully apply these prescriptions.

3.1.

General recommendations

• Installation and maintenance must be carried out with the unit

totally disengaged from its drive system and must be performed by

qualified personnel.

• Use adequate clothing (avoid ties, loose sleeves, necklaces and

so on) and suitable protection equipment (gloves, protection glasses,

boots...).

• To prevent errors and hazardous situations, establish what each

operator is responsible for in the different maintenance operations.

• When transporting the Julia group, use proper slinging. Store the

pump in stable places.

• Make sure that all the parts of the unit are idle and cool, before

performing any maintenance operation.

• Before each maintenance operation, stop the pump and restore

the atmospheric pressure.

• When the pump is running, some parts may reach very high

temperatures (above 100°C). Use all necessary precautions to avoid

contact.

• Operators working nearby must avoid prolonged exposure to the

noise emitted by the aspirator, if not equipped with the proper ear-

protection devices.

• Avoid accidental suction of solids: solids may be projected at high

speed through the exhaust manifold and cause injures.

• Do not introduce hands or objects inside the pump ports during

functioning.

• Do not start the machine if the protection devices provided for

transmissions are removed. Replace damaged parts.

• Pressure relief valve: point the air flux away from the operators.

• Do not use the aspirator over its designed limits: the machine may

be damage and the operator may be injured.

Do not exceed the power supply parameters

indicated in the technical tables (see par. 2.1, 2.2,

2.3 and 2.4).

3.2.

Intended use

• Julia 3000-5000-7000-8000-8500-9000 units, composed of

vacuum pump and centrifugal pump, are built for installation upon

trailers for agriculture application. Vacuum pump is used for suction or

discharge of the tank used for manure transportation. The centrifugal

pump instead is used for pressure spreading of manure.

• Julia 7000 HP unit, composed of vacuum pump and high pressure

pump, is suggested for installation upon trailer. The vacuum pump is

used for loading and discharge of the manure tank. The high pressure

piston pump is used for washing operations by means of clean water

(usually loaded inside a suitable tank compartment).

• Liquids or solids infiltrations can seriously damage the pump.

• Do not run the pump over its designed operating limits (see par.

2.1, 2.2, 2.3 and 2.4): it may break and transmission can be damaged.

3.3.

Conveyed fluids

• The Julia group vacuum pump is suitable for conveying filtered air:

if other types of gas are sucked, check compatibility with the machine

characteristics. Jurop has a technical service at disposal for any kind of

information.

• The introduction of foreign matter or liquids in the vacuum pump or

the introduction of large-sized foreign matter in the centrifugal pump

may damage the Julia group. Install a suction filter. In case of

occurrence, immediately stop the machine and clean.

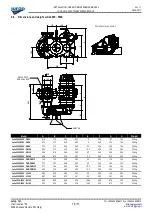

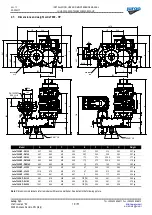

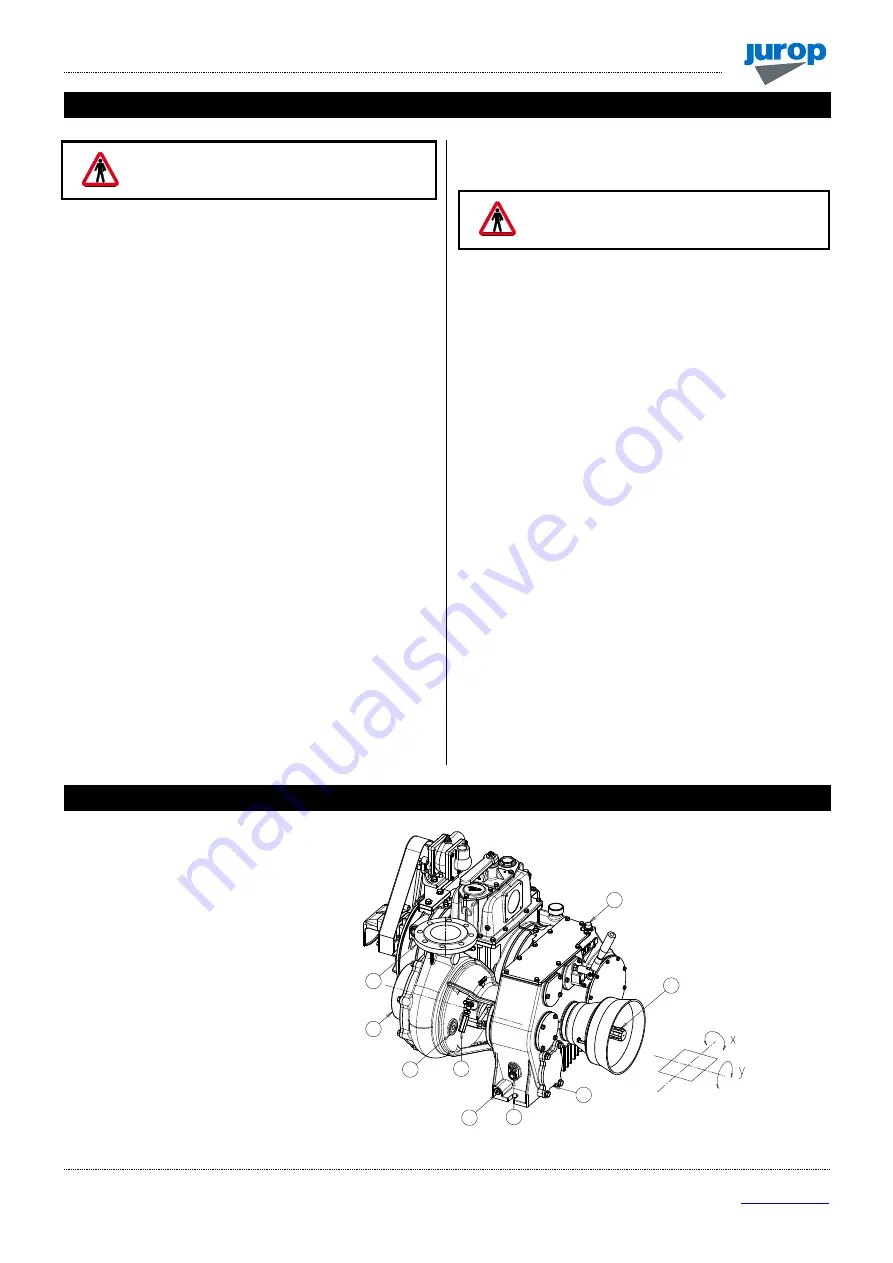

Legend of main components

1.

Splined shaft

2.

Oil filling port

3.

Oil level indicator

4.

Oil drain plug

5.

Hydraulic pump Intake

6.

Greaser (optional)

7.

Mechanical seal plug. Remove to wash the

mechanical seal

8.

Inlet centrifugal pump

9.

Outlet centrifugal pump

Fig. 4.1

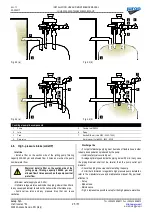

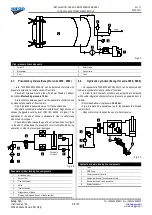

4. Installation

3. Safety and accident prevention