REV

.

11

30-05-2017

INSTALLATION

,

USE AND MAINTENANCE MANUAL

JULIA 3000-5000-7000-8000-8500-9000

-

HP

24 / 51

Jurop

SpA

Via Crosera n° 50

33082 Azzano Decimo, PN (Italy)

T

EL

.

+39

0434

636811

F

AX

.

+39

0434

636812

http://www.jurop.it

e-mail: info@jurop.it

α

α

1

α

α

1

4.1.

Checking upon receipt

• Remove packaging and eliminate material that could be

dangerous if sucked.

• When the goods are delivered, make sure that all parts listed on

the delivery note are in perfect condition and have suffered no damage

during shipping.

• Make sure the Julia group end the vacuum pump has its

identification plate affixed on the front cover. Pumps without such

identification are to be considered anonymous and potentially

dangerous: in such an event, they must not be used, otherwise the

manufacturer will be deemed free from any liability whatsoever.

• If the machine does not intend to be used for a long time it must

be stored in a closed dry place, the intake and exhaust ports need to

be protected with suitable caps in order to avoid the introduction of

foreign matter that could block or compromise subsequent functioning

and the overall state of conservation must be periodically renewed.

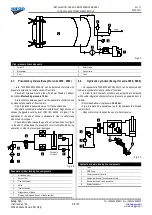

4.2.

Mounting

• The mounted Julia group must be accessible for maintenance and

firmly fixed on a frame or angled base with a 3° max inclination on x

and y axes. The structure must be fit to avoid flexions or vibrations.

• Make sure that there is enough free room around the pump for a

correct air cooling circulation and protect the pump from the exposure

to dirt and debris.

• Prepare the necessary space for an easy access to the lubrication

check-points (tank level and gear box, oilers, ecc).

• Mind the room necessary to levers operation.

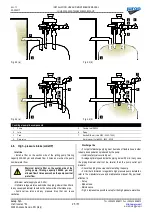

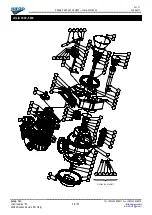

4.3. Cardan shaft drive

• Use telescopic cardan shafts.

Fig. 4.2

• In order to achieve a uniform motion of the driven shaft, the

following requirements must be met (see Fig. 4.2):

- Equal working angle α and α1 of both couplings;

- The internal fork joints must be coplanar;

- Both driven and driving shafts must be coplanar.

• It is also recommended working with limited articulated joint angles

(max 15°) and disengaging the transmission for those operations

requiring great angles (steering or lifting).

Follow the rotation direction as indicated on the

front flange. Follow the instructions of the cardan

shaft’s manufacturer.

• Use the protection that comes with the Julia group shaft.

Use the cardan protection supplied with the

pump. The pump installation must fulfill the

current EC injury prevention specifications.

4.4.

Vacuum pump set up

• When setting up the vacuum system, follow the instructions

included in the use and maintenance manual.

Pay particular attention to the following paragraphs:

-

Connection to tank;

-

Pump start up;

-

Use;

-

Maintenance.

• The following accessories are available for the vacuum pump:

-

Exhaust silencer (vacuum pump);

-

Suitable safety filter and/or purifier on vacuum line (compulsory) to

avoid suction of foreign matter or liquids;

-

Suitable safety valves.

4.5.

Centrifugal pump set up

• It is necessary to install a DN200 flexible joint on the centrifugal

pump suction side.

Warning: install a DN200 flexible joint on the

centrifugal pump suction side.

• Avoid solids suction inside centrifugal pump.

Warning: avoid solids suction inside centrifugal

pump.

• Install a gate valve on the centrifugal pump exhaust side in order

to keep vacuum inside the tank while it is loading.

• Picture 4.3 shows an example of proper installation of Julia unit

complete with 1 lever to alternate running one of the two outlets: a)

vacuum the material in the tank b) discharge the tank..

• Figure 4.4 shows an example of proper installation of Julia unit

complete with 2 levers to alternate-combine running (a & b). The

loading of the tank is made thanks to the combined running of the

vacuum and centrifugal pump (a). Use the centrifugal pump only to

discharge the tank (b).