REV

.

11

30-05-2017

INSTALLATION

,

USE AND MAINTENANCE MANUAL

JULIA 3000-5000-7000-8000-8500-9000

-

HP

25 / 51

Jurop

SpA

Via Crosera n° 50

33082 Azzano Decimo, PN (Italy)

T

EL

.

+39

0434

636811

F

AX

.

+39

0434

636812

http://www.jurop.it

e-mail: info@jurop.it

1

2

3

6

4

4

5

4

7

5

4

4

6

1

2

4

5

7

3

3

3

4

4

4

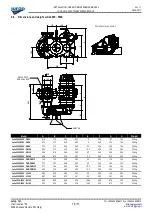

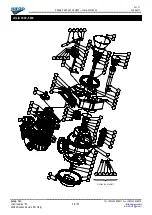

Fig. 4.3 (a)

Fig. 4.3 (b)

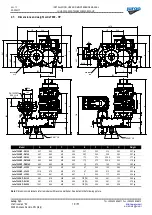

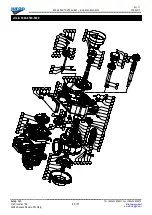

Fig. 4.4 (a)

Fig. 4.4 (b)

Centrifugal pump line components

1

Pump

5

Flexible Joint DN200

2

Julia

6

Piping

3

Tank

7

Nozzle Ø34 mm (Julia 3000 - 5000 - 7000)

4

Gate valve

Slurry injector ) Julia 8000 - 8500 - 9000)

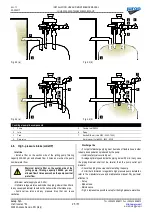

4.6.

High - pressure intake

(Julia HP)

Inlet line

• Install a filter on the suction side of the jetting pump, filtering

capacity 200-360 µm and allowed flow 3 times as much as the pump

nominal water flow.

Warning: install a filter on the suction side of the

jetting pump, filtering capacity 200-360 µm and

allowed flow 3 times as much as the pump nominal

water flow.

• Minimum water supply head: 0.20 m.

• Optimal average water speed inside the piping: slower than 0.5m/s.

In any case pipe diameter should not be narrower than the intake pipe.

• Avoid narrow turns and any pressure drop that can cause

cavitation.

Discharge line

• First part of discharge piping must be made of flexible hose in order

to damp down pulsations produced by the pump.

• Install a safety valve correctly set.

• Average optimal speed inside the piping: below 5,5 m/s. In any case

the piping diameter shall not be smaller than the pump outlet port

diameter.

• Check the piping to be clean before starting the pump.

• For further information in regards to high pressure pump installation,

refer to the manufacturer use and maintenance manual. Pay particular

attention to:

-

Set up;

-

Mode of use;

-

Maintenance.

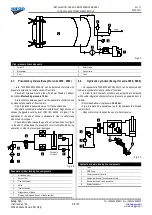

• Fig 4.4 represents a possible set up for the high pressure water line.