REV

.

11

30-05-2017

INSTALLATION

,

USE AND MAINTENANCE MANUAL

JULIA 3000-5000-7000-8000-8500-9000

-

HP

26 / 51

Jurop

SpA

Via Crosera n° 50

33082 Azzano Decimo, PN (Italy)

T

EL

.

+39

0434

636811

F

AX

.

+39

0434

636812

http://www.jurop.it

e-mail: info@jurop.it

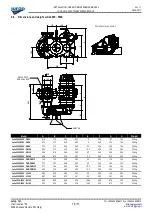

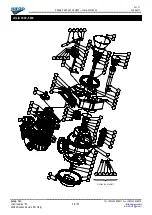

Fig.4.5

High - pressure line components

1

Julia HP

4

Safety valve

2

Manometer

5

Control valve

3

Filter

6

Tank

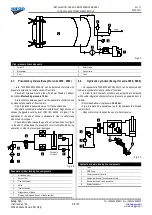

4.7.

Pneumatic cylinders (Except for Julia 3000 - 5000)

• Julia 7000-8000-8500-9000-HP can be delivered complete with

pneumatic cylinders for remote control of functions.

• Pneumatic cylinders must be fed with 20 µm filtered air without

lubrication.

Max feeding pressure 10 bar

.

• Avoid collisions between gears: set the pneumatic cylinder speed

by means of pneumatic air flow controls.

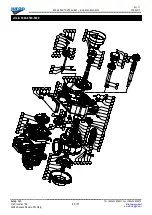

• Fig 4.5 represents a possible set up for the pneumatic line.

• Pneumatic cylinders are suitable for installation of magnetic end of

strokes (Suggested security level IP65 IEC 60529 or higher). The

application of the end of stroke is advisable in order to understand

when the exit is in gear.

• Pneumatic cylinder keeps the gear in correct position once it gets

to the end of stroke Keep the pneumatic circuit constantly fed during

operation, in order to prevent gear damages.

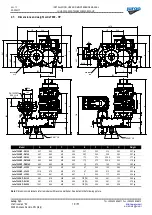

Fig. 4.6

Pneumatic cylinder feeding line components

1

Air feeding point

2

Suction filter

3

Flow controllers

4

Valve

5

Flow controllers

6

Magnetic end of stroke

7

Warning light (signals the end of stroke position)

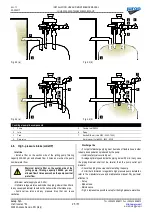

4.8.

Hydraulic cylinders (Except for Julia 3000 - 5000)

• On request Julia 7000-8000-8500-9000-HP can be delivered with

hydraulic cylinders for remote control of functions.

• In order to limit hydraulic cylinder push, actuators are delivered

with double integrated shockproof valve (pressure on powered duct is

limited).

• Recommended service pressure:

30-40 bar.

• Fig. 4.6 represents a possible set up for the hydraulic line (Closed

center circuit).

• Open center circuit required the use of a blocking valve.

Fig. 4.7

Hydraulic actuators feeding line components

1

Tank

2

HDR Pump

3

Overpressure safety valve

4

Hydraulic distributor (closed center circuit)

5

Double shockproof valve (enclosed)

6

Hydraulic actuator

P

NEUMATIC

CYLINDER

2

5

4

1

3

6

7

1

2

3

4

5

6

1

3

2

4

5

6