REV

.

11

30-05-2017

INSTALLATION

,

USE AND MAINTENANCE MANUAL

JULIA 3000-5000-7000-8000-8500-9000

-

HP

30 / 51

Jurop

SpA

Via Crosera n° 50

33082 Azzano Decimo, PN (Italy)

T

EL

.

+39

0434

636811

F

AX

.

+39

0434

636812

http://www.jurop.it

e-mail: info@jurop.it

• Installation and maintenance must be operated only by qualified personnel.

• The following scheme indicates the main checks to be completed and their intervals.

Operating

Condition

Maintenance area

Checking

8

H

50

H

500

H

1000

H

1500

H

O

PERATING

Julia Group

Lubrication

Rotating speed

Working pressure

Noise

S

TANDSTILL

Vacuum Pump

Check the oil level (both tank and gearbox)

Clean filter

Check vanes wear

Centrifugal Pump

Clean filter

Centrifugal pump washing (*)

Gear box oil level

Seal: check and greasing

Oil change (gear box)

PTO Pump

Transmission joint: lubricate with grease (**)

High pressure pump

Oil change; valves and seals check (see pump manual)

Transmission joint: lubricate with grease

Overall

Shaft axe: check

(*): Wash the centrifugal pump more often in case thick sludge is sucked. Wash

the impeller before a long period of stand-by.

(**): Lubricate the transmission joint when a check of the system is required or

during a pump’s review.

6.1. Ordinary maintenance

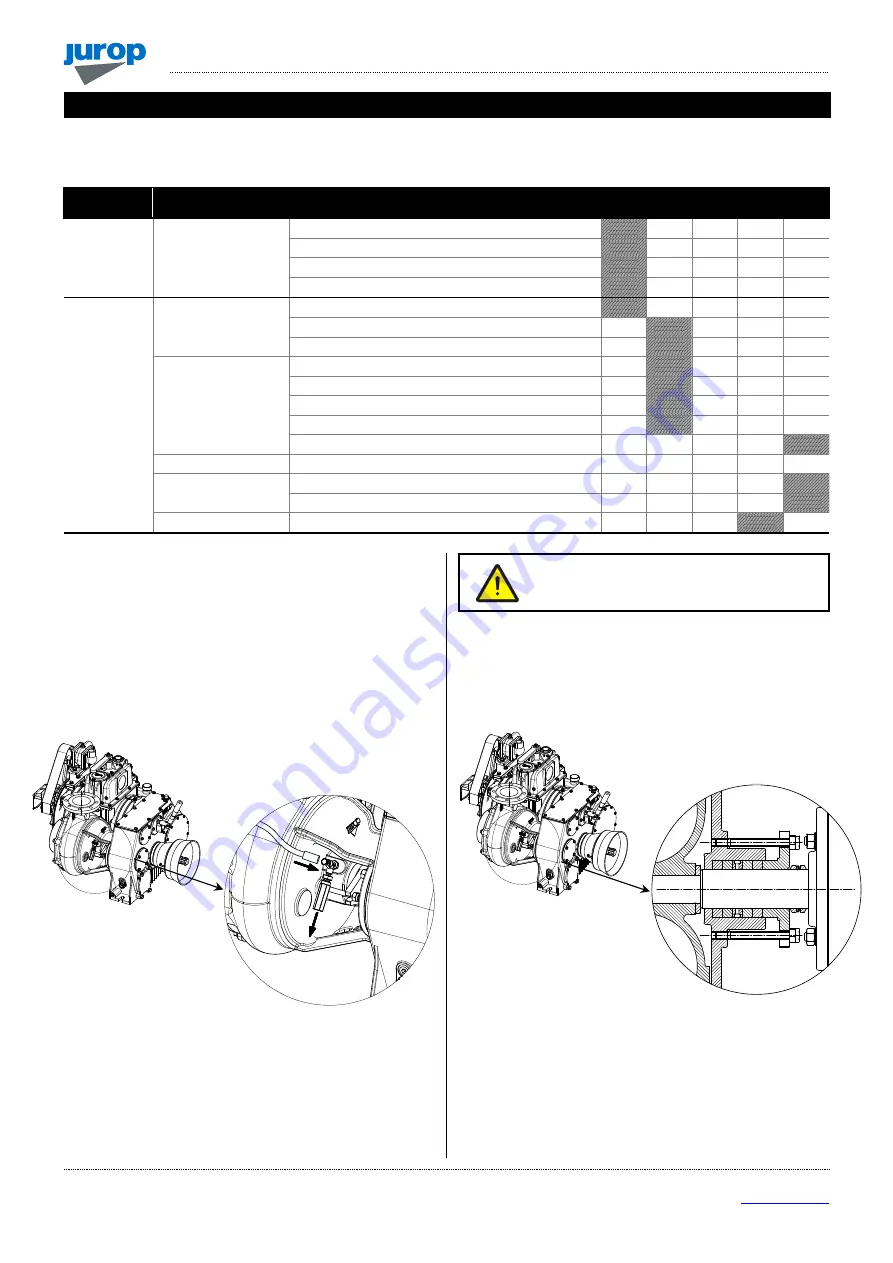

• Packing seal greasing (optional): periodically, with NLGI 2 grease.

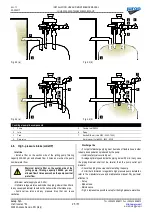

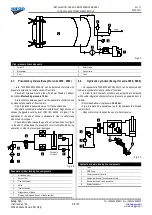

Fig. 6.1 describes the correct procedure for the packing seal greasing.

Fig. 6.1

• Checking seal tune: seal rings must be clean; for the placement

proceed one at a time and turn them about 90° to each other.

• Packing seal tune: fasten the screws acting on the fork. Do no

tight excessively as the screws may break.

Warning: do not excessively fasten the screws

acting on the fork, as they may break.

• Start up the centrifugal pump and check if the leakage has been

stopped.

• If the leakage does not stop or does not slow down, replace the

packing seal.

• Fig. 6.2 shows the correct packing seal correct set up.

Fig. 6.2

• Mechanical seal: The liquid cools down and lubricates the seal.

• Periodically suck clean water in order to grant the correct

operation. Alternatively, wash the housing inside by pouring clean

water through the service hole.

• Fig. 6.3 shows the correct cleaning of the mechanical seal.

6. Maintenance