18

www.juwent.com.pl

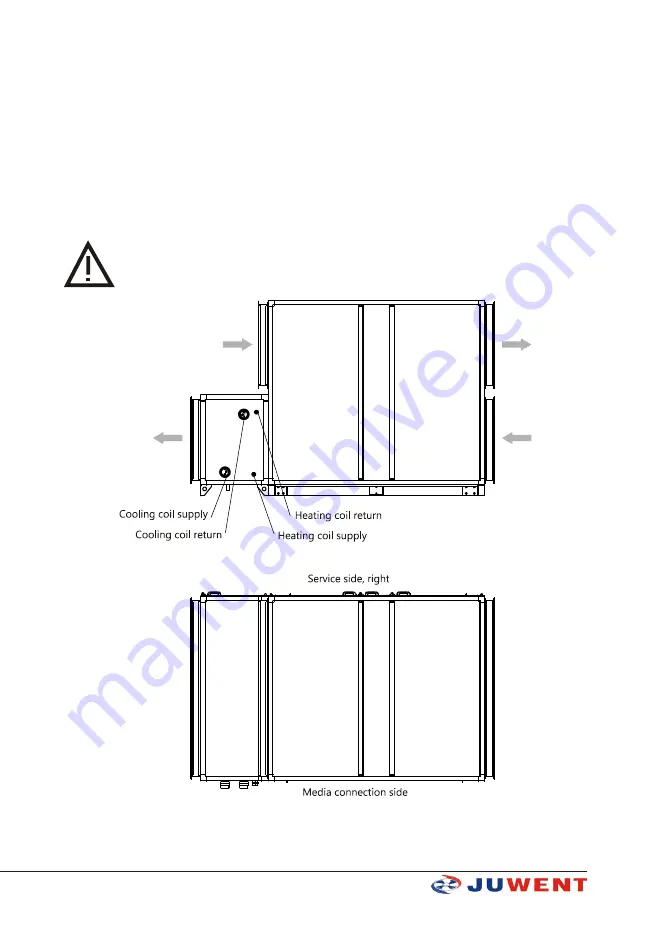

11.6. CONNECTING HEATING AND COOLING COILS

Connecting heat exchangers should be completed so as to protect them against possible stresses

which could cause mechanical damages or leaks. Connections on heat exchangers should not

be affected by weight of the pipework or thermal stresses. Depending on local conditions use

compensation in pipework system on supply and return in order to reduce length-wise expansion of

pipeworks. During installation of the supply system to heat exchangers with threaded connection,

heat exchanger connection should be locked using an additional wrench. The supply system should

be arranged so that it creates no interference in access to other sections of the unit. Supply and

return connections on heat exchangers should be connected so as the heat exchanger operates in

counter-flow system. Operation in counter-flow system reduces average difference in temperature

which determines the heat exchanger efficiency.

Connection of freon cooling coil to the supply system with refrigerating unit should be

carried out by a qualified cooling system technician in accordance with valid rules for

freon condensation equipment.

Fig. 5. Location of connecting pipes