14

www.juwent.com.pl

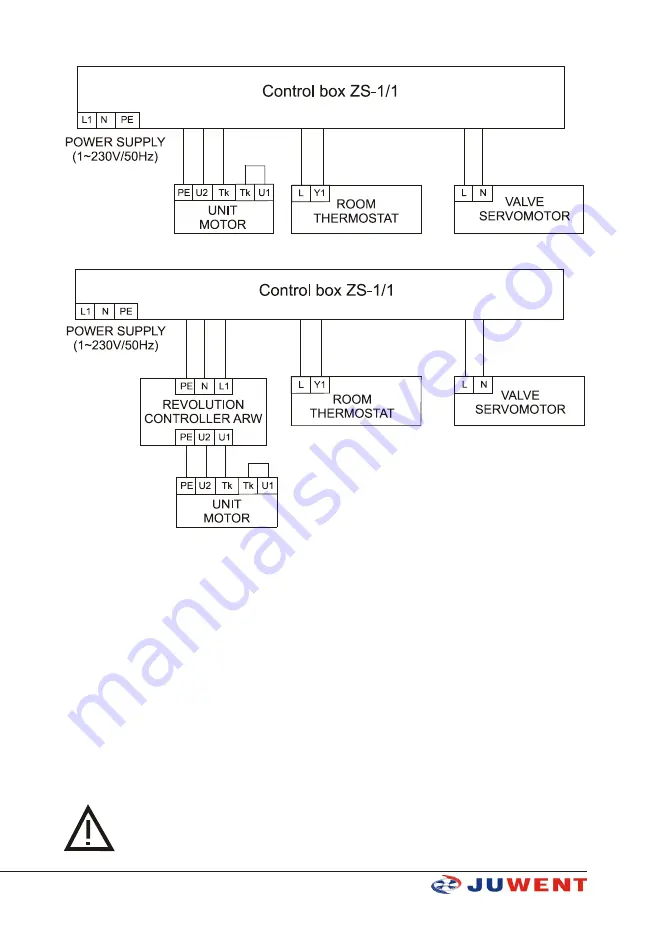

Fig. 5. Connection diagram of unit automatics without controller ARW

Fig. 6. Connection diagram of unit automatics with controller ARW

11. DEVICE STARTUP

Prior to the startup it is necessary to:

»

check up the fastening state of the unit;

»

check up the leak tightness of water or steam connections;

»

check up the supply voltage according to the electric plate;

»

check up the additional protection of the fan and unit casing;

»

check up the correctness of the electric connection of the motor.

To switch on the unit it is necessary to:

»

open the valves of heating medium;

»

switch on the current supply to the electric motor;

»

adjust the supply air stream direction and range by means of the outlet grid blades.

To switch off the unit it is necessary to:

»

limit the heating medium flow to the heater of the unit;

»

switch off the current supply to the electric motor of the fan.

In case of long standstills of the unit or breaks of heating network operation the heater

should be drained and the cut-off valves should be closed, if need be.