16

www.juwent.com.pl

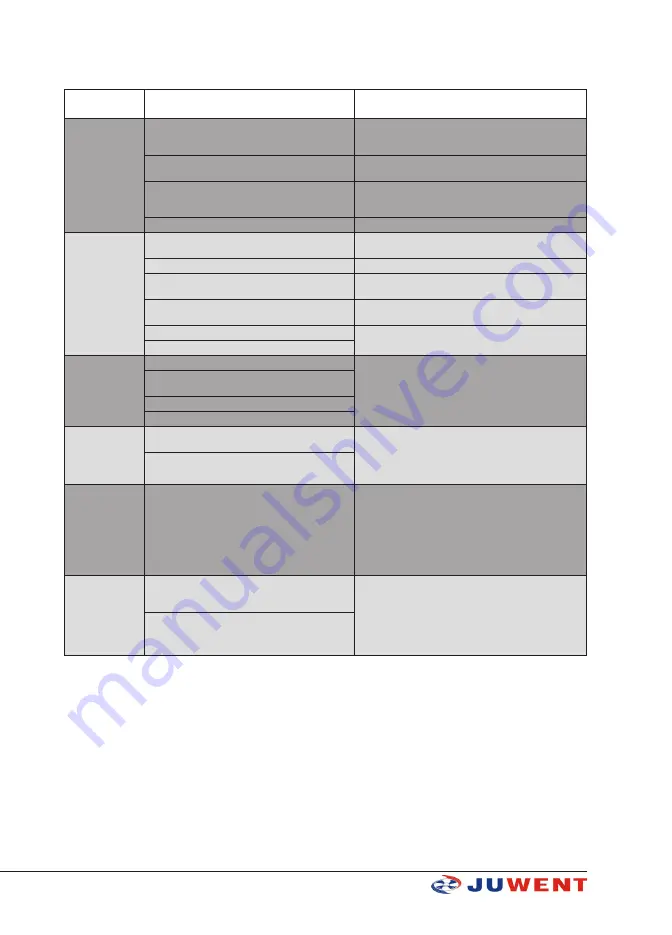

13. TROUBLESHOOTING

Trouble

description

Possible trouble cause

Troubleshooting

heat exchanger le-

akage

mechanical damage of heat exchanger (it may easy

appear when the unit is connected to the installation

without taking care

use a locking spanner to mount with the installation de-

finitely

exceedance of admissible heating medium para-

meters

connect the unit with the heating installation protected

against the excessive pressure and temperature growth

heat exchanger freeze

use an antifreeze thermostat, antifreeze heating fluids or

remove water from the unit within the period of standstill

and freeze risk

use of the unit in the aggressive environment

too load operation

of the unit

minimum distance from the wall or ceiling is not

maintained

use distances recommended in the instruction manual

improper revolution direction

execute a proper electric connection

improper parameters of the mains

use the unit only when the parameters of the mains and

the unit are compliant

air outlet is blocked by outlet grid louvres

avoid a significant closing of outlet grid louvres at high

speed ratios

fan vibrations, the blades rub against fixed elements check up the correctness of the fan and fastening reliabi-

lity of other elements of the unit

not centric fastening of the fan in its bearing plate

fan does not work

incorrect or unreliable electric connections

check up or correct:

1) compliance of electric connections according to the

diagrams specified in the instruction manual

2) reliability of connections on electric terminals

3) parameters of the mains

improper parameters of the mains (lack of three

phases in three-phase motors)

fan motor is damaged

fan operation control elements are damaged

Revolution con-

troller

ARW/RTRD does

not work

correctness of electric connections (whether the le-

ads are just clamped in the electric terminals)

check up or correct:

1) compliance of electric connections according to the

diagrams specified in the instruction manual

2) reliability of connections on electric terminals

3) parameters of the mains

only 1 controller can be connected to 1 unit

Servomotor does

not open the valve

correctness of thermostat operation (characteristic

“tick” when switching)

check up or correct:

1) compliance of electric connections according to the

diagrams specified in the instruction manual

2) reliability of connections on electric terminals

3) parameters of the mains

4) whether the servomotor reacts to an electric pulse. If

the servomotor damage is stated, the damaged element

should be claimed.

Room thermostat

does not apply the

signal

more than one unit is connected directly to the

thermostat (larger number means the thermostat

overload)

check up or correct:

1) compliance of electric connections according to the

diagrams specified in the instruction manual

2) reliability of connections on electric terminals

3) parameters of the mains

4) if there is no characteristic “tick”, the thermostat is me-

chanically damaged and should be claimed.

mounting place of the thermostat in the room

14. INFORMATION

As to all issues concerning the TROPIC heating units please contact JUWENT Production Plant or

Representatives