Chapter 5---Electronics

5-52

Model 250 Service Manual

Image - image light that passes through Relay Lens and focuses on photosensitive

layer on input side of ILA

®

.

CRT/Yoke Assemblies - Operation

The CRTs receive image signals that come from the VICs to the Video Processor

PCB, to the Video Amplifier PCB. The image information drives an electron gun

inside the CRT. The Cathode of the CRT is a small, metal oxide disk that covers

the filament heater. The filament heater heats the Cathode causing it to emit

electrons. The electrons travel forward to the positively charged CRT Anode. As

the electrons travel forward in the CRT, they pass through control grids, each one

more positively charged than the next.

The first grid G

1

is a small aperture that is negatively charged with respect to the

Cathode. The negative bias voltage allows the beam current to be controlled by

the video signal applied between G

1

and the Cathode to modulate brightness.

The G

2

control grid restricts the beam of electrons to a narrow path and

accelerates them because of its positive voltage. The G

3

grid works with G

2

to

form an electrostatic focusing lens that focuses the electron beam on the CRT

phosphor.

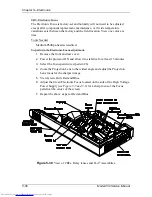

The Deflection Yokes use magnetism to deflect the electron beam horizontally or

vertically inside the CRT. The Deflection Yokes deflect the electron beam at right

angles, so the Horizontal Deflection Yokes are on the top and bottom of the CRT.

The Vertical Deflection Yokes are on the left and right sides. Both the horizontal

and vertical deflection waveforms come from the Horizontal Vertical Deflection

PCB. Geometric, Convergence, and Shading correction information is add to the

deflection waveforms to adjust them so they create a centered, linear uniform

image on the screen.

Each CRT is encased in a metal shroud made of Mu metal. This shroud protects

the CRT from stray magnetism from PCBs, cooling fan motors and the

magnetism from other CRTs. The stray magnetism can influence the CRT Yoke

magnetism causing noise and distortion on the screen.

CRT/Yoke Assemblies - Service Adjustments

NOTE:

It is recommended that the CRT Mechanical Focus procedure and the

CRT Rotation procedure be done sequentially. This means that the CRT

Mechanical Focus procedure should be performed immediately followed by the

CRT Rotation procedure or vice versa. The reason for this is there are two

setscrews, one on either side of the Guide Plate, that hold the CRT in position.

Loosening the setscrews to perform one adjustment may cause the other

adjustment to change; therefore, both adjustments should be performed at the

same time.

Summary of Contents for 250

Page 16: ...Chapter 2 System Description Model 250 Service Manual 2 9 ...

Page 43: ...Chapter 4 Optical 4 10 Model 250 Service Manual Figure 4 6 Optical Path ...

Page 55: ...Chapter 5 Optical 3 4 22 Model 100 Service Manual ...

Page 91: ...Chapter 5 Electronics 5 36 Model 250 Service Manual Figure 5 22 Scan Reversal PCB I O Diagram ...

Page 131: ...Chapter 5 Electronics 5 76 Model 250 Service Manual Figure 5 44 Backplane Diagram right side ...

Page 132: ...Chapter 5 Electronics Model 250 Service Manual 5 77 ...

Page 138: ...Chapter 6 Miscellaneous Items 6 6 Model 250 Service Manual ...

Page 167: ...Chapter 7 Troubleshooting Model 250 Service Manual 7 29 ...

Page 181: ...Chapter 8 Software and Protocol 8 14 Model 250 Service Manual ...

Page 185: ...Chapter 9 Parts List 9 4 Model 250 Service Manual ...