Chapter 4---Optical

Model 250 Service Manual

4-3

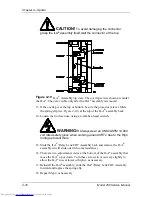

CAUTION

!

Fan disconnection is acceptable for a short

period of time only (preferably <20 minutes--maximum 45 minutes).

WARNING!!!

Dangerous levels of ultraviolet and

infrared radiation, dangerous glare, very high temperatures (180°C to

300°C) and high internal gas pressure are present at the Xenon Arc

Lamp. Protect eyes from ultra violet light and infrared light by using

X5

(375 to 700 nanometers), ANSI approved, shade goggles when

actually working on the projector near the arc lamp source.

6.

Access the "Shutters on Hide" box again from the System-Preferences

menu and uncheck the box, then use the RGB and HIDE keys to hide

Green. This mutes video from the Green CRT but leaves the Green shutter

open to allow Arc Lamp light from the Green ILA

®

to display on the

screen.

7.

Select ILA

®

Bias from the System-Factory Adjustments menu. Record the

current ILA

®

bias level. Return to this bias level when this adjustment is

complete. Record only the Green ILA

®

bias value because Red and Blue

will return to their original levels when Green is reset.

8.

Use the up-arrow key and adjust the ILA

®

bias for Green for maximum

light output.

9.

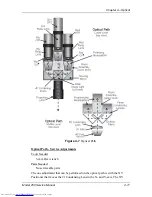

Adjust the Arc Lamp alignment screws (see Figure 4-2) to center the "hot

spot" (brightest area). Figure 4-1 illustrates a "hot spot" on the screen.

NOTE:

It is easier to perform the following procedure with one person

standing in front of the screen holding a light meter and another person

making the adjustments to the Arc Lamp

.

10.

Use the light meter to locate the brightest area or “hot spot”, (see Figure

4-1). Move the light meter around the screen to determine where the hot

spot is located. The “hot spot” will be where the light reading is highest.

11.

Adjust screw 1, 2, or 3, (see Figure 4-2) to move the hot spot to the center

of the screen. Moving the “hot spot” will generally require adjusting two

or more screws. Adjusting all three screws adjusts the Arc Lamp on the z-

axis. Adjusting the three screws clockwise increases light output and

rolloff.

12.

Check for maximum brightness and readjust the z-axis as necessary after

setting the x-axis and again after setting the y-axis.

13.

Tighten spider lock down bolt.

Summary of Contents for 250

Page 16: ...Chapter 2 System Description Model 250 Service Manual 2 9 ...

Page 43: ...Chapter 4 Optical 4 10 Model 250 Service Manual Figure 4 6 Optical Path ...

Page 55: ...Chapter 5 Optical 3 4 22 Model 100 Service Manual ...

Page 91: ...Chapter 5 Electronics 5 36 Model 250 Service Manual Figure 5 22 Scan Reversal PCB I O Diagram ...

Page 131: ...Chapter 5 Electronics 5 76 Model 250 Service Manual Figure 5 44 Backplane Diagram right side ...

Page 132: ...Chapter 5 Electronics Model 250 Service Manual 5 77 ...

Page 138: ...Chapter 6 Miscellaneous Items 6 6 Model 250 Service Manual ...

Page 167: ...Chapter 7 Troubleshooting Model 250 Service Manual 7 29 ...

Page 181: ...Chapter 8 Software and Protocol 8 14 Model 250 Service Manual ...

Page 185: ...Chapter 9 Parts List 9 4 Model 250 Service Manual ...