Chapter 5---Electronics

5-10

Model 250 Service Manual

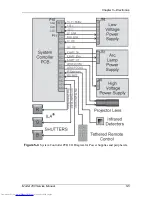

Controller PCB also enables the selected VICs through the IIC bus based on the

VIC selected on the Channel Menu.

The System Controller PCB generates the on-screen menus and test pattern

overlays and sends them to the Video Processor PCB. It sends the X and Y

Convergence correction data to the Convergence Deflection PCB. It sends

Threshold and Sensitivity shading data to the Video Processor PCB for the all

three colors. The System Controller PCB stores all the configuration data such as

Geometry, Convergence, Shading, ILA

®

Bias and Sensitivity, and G2 settings etc.

in flash memory and allows that data to be exported to, or imported from a floppy

disk.

The System Controller PCB displays system status through a single three-color

LED visible on the back panel. A green light indicates normal operation, the

yellow indicates standby operation, and red indicates a fault or error condition.

The System Controller PCB has an External Service Mode Switch that enables the

operator to switch from the normal operating mode to a diagnostic mode. If there

is a new release of system software, it can be uploaded into the projector by

switching into the diagnostic mode. The procedure for this is in the Software and

Protocol section (see Chapter 8, Software and Protocol).

System Controller PCB - Remove and Replace

Tools Needed

#1 Pozi-drive Phillips-head screwdriver

#0 Pozi-drive Phillips-head screwdriver

Parts Needed

System Controller PCB - p/n 104678

To remove the System Controller PCB:

1.

Power OFF the projector by IR Remote or PC, and allow the cooling fans

to run until they shut off automatically.

2.

Turn the AC Circuit Breaker to the OFF position and unplug the AC

Power Cord.

3.

Disconnect all the external source video cables and control cables.

4.

Remove the rear cover.

5.

Remove the Back Panel. Remove the nine Pozi-drive Phillips-head

retaining screws using the #1 Pozi-drive Phillips screwdriver.

6.

Remove the Connector Bracket by removing the single Pozi-drive

Flathead Phillips-head screw using the #0 Pozi-drive Phillips screwdriver.

7.

Pull the black Card Extractor handles back to disconnect the System

Controller PCB connector and pull the PCB out of the Electronics Module.

8.

Reverse the procedure to install the System Controller PCB.

Summary of Contents for 250

Page 16: ...Chapter 2 System Description Model 250 Service Manual 2 9 ...

Page 43: ...Chapter 4 Optical 4 10 Model 250 Service Manual Figure 4 6 Optical Path ...

Page 55: ...Chapter 5 Optical 3 4 22 Model 100 Service Manual ...

Page 91: ...Chapter 5 Electronics 5 36 Model 250 Service Manual Figure 5 22 Scan Reversal PCB I O Diagram ...

Page 131: ...Chapter 5 Electronics 5 76 Model 250 Service Manual Figure 5 44 Backplane Diagram right side ...

Page 132: ...Chapter 5 Electronics Model 250 Service Manual 5 77 ...

Page 138: ...Chapter 6 Miscellaneous Items 6 6 Model 250 Service Manual ...

Page 167: ...Chapter 7 Troubleshooting Model 250 Service Manual 7 29 ...

Page 181: ...Chapter 8 Software and Protocol 8 14 Model 250 Service Manual ...

Page 185: ...Chapter 9 Parts List 9 4 Model 250 Service Manual ...