Chapter 5---Electronics

Model 250 Service Manual

5-15

The G

2

voltage accelerates the electrons that are emitted from the cathode of the

CRT. The CRT filament emits the electrons and G

1

voltage regulates the amount

of electrons that are emitted from the cathode. The G

2

voltage is adjusted through

the menu (Black Level). The Video Processor PCB receives the G

2

control data

for each color through the IIC bus and sends an analog voltage to the Video

Amplifier PCB to control the G2 voltage.

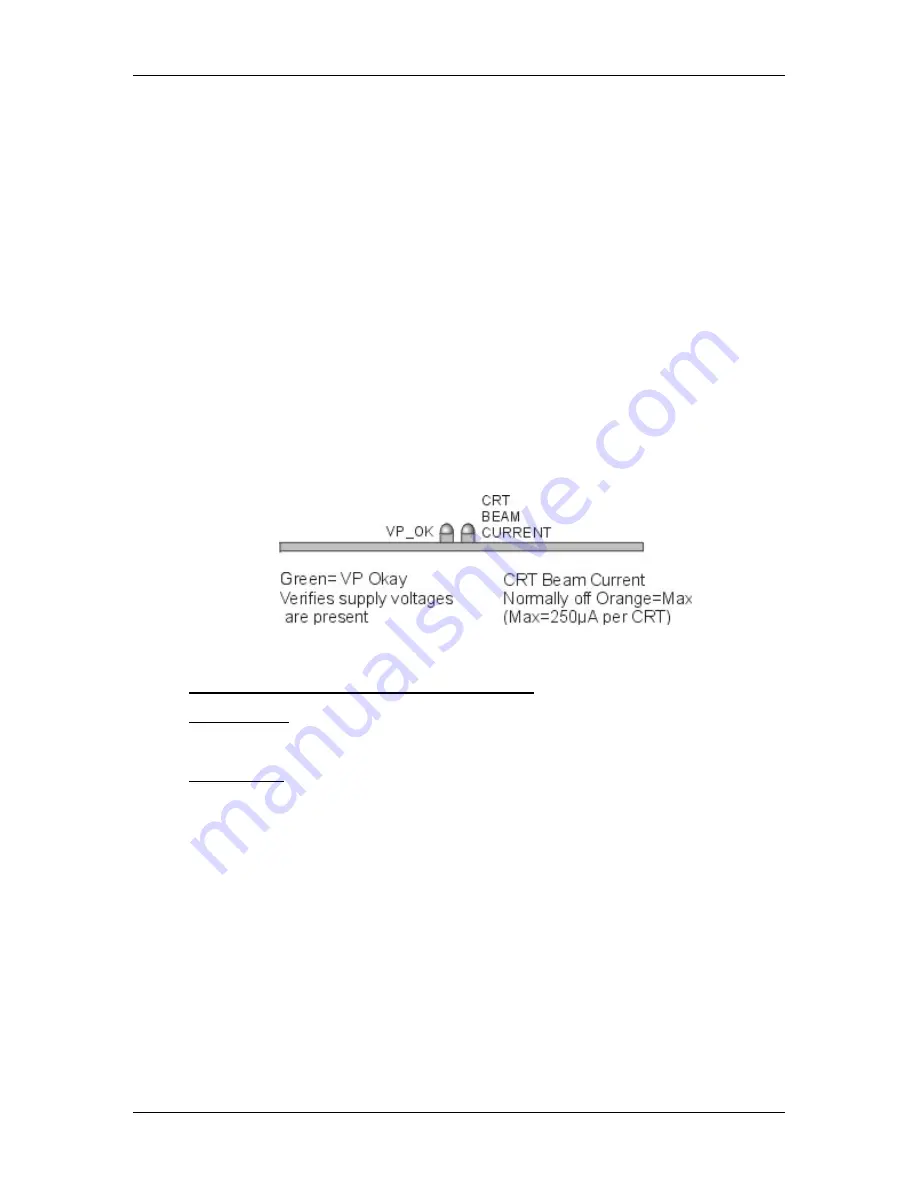

The Video Processor PCB protects the CRTs from excess beam currents to

prevent it from burning the phosphor. The Video Amplifier PCB sends a sample

of the beam current (RGB_BEAM) for each CRT back to the Video Processor

PCB. The Video Processor PCB compares this sample to a preset value. If the

sample beam current is higher than the preset value, the Video Processor PCB

reduces the contrast for the CRT with high beam current. If the CRT beam current

is still high, it then reduces the G

2

voltage. The maximum beam current is 250 µA

per CRT.

The Video Processor PCB receives the G1_BIAS signal from the System

Controller PCB through the IIC bus and sends a voltage to the Video Amplifier

PCB to set the brightness level.

Figure 5-9

Video Processor PCB LEDs.

Video Processor PCB - Remove and Replace

Tools Needed

#1 Pozi-drive Phillips-head screwdriver

Parts Needed

Video Processor PCB - p/n 105234

To remove the System Controller PCB:

1.

Power off the projector by IR Remote or PC, and allow the cooling fans to

run until they shut off automatically.

2.

Turn the AC Circuit Breaker to the OFF position and unplug the AC

Power Cord.

3.

Disconnect all the external source video cables and control cables.

4.

Remove the rear cover.

5.

Remove the Back Panel by removing the nine Pozi-drive Phillips-head

retaining screws using the #1 Pozi-drive Phillips screwdriver.

Summary of Contents for 250

Page 16: ...Chapter 2 System Description Model 250 Service Manual 2 9 ...

Page 43: ...Chapter 4 Optical 4 10 Model 250 Service Manual Figure 4 6 Optical Path ...

Page 55: ...Chapter 5 Optical 3 4 22 Model 100 Service Manual ...

Page 91: ...Chapter 5 Electronics 5 36 Model 250 Service Manual Figure 5 22 Scan Reversal PCB I O Diagram ...

Page 131: ...Chapter 5 Electronics 5 76 Model 250 Service Manual Figure 5 44 Backplane Diagram right side ...

Page 132: ...Chapter 5 Electronics Model 250 Service Manual 5 77 ...

Page 138: ...Chapter 6 Miscellaneous Items 6 6 Model 250 Service Manual ...

Page 167: ...Chapter 7 Troubleshooting Model 250 Service Manual 7 29 ...

Page 181: ...Chapter 8 Software and Protocol 8 14 Model 250 Service Manual ...

Page 185: ...Chapter 9 Parts List 9 4 Model 250 Service Manual ...