32

AV-20FD24

No. 52133

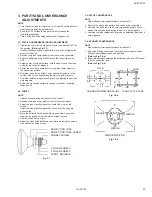

GOOD PICTURE BUT NO SOUND

Yes

No

Yes

No

Insert CD301 and CD302.

Check Sound+B line and

peripheral circuit.

Check IC301, speaker and

Earphone jack.

Yes

No

Is CD301 and CD302

inserted?

Is the voltage at pin 10

of IC351 DC 21.5V ?

Is the voltage at pin 8

of IC351 LESS than DC

2.0V ?

Check IC101 and peripheral circuit.

Yes

Is the voltage at pin 11

of IC351 DC 10.3V ?

Check P.CON+12V line and

peripheral circuit.

No

Yes

Is the AUDIO OUT

signal at pins 7 and 11 of

IC301?

Check A_OUT_L, A_OUT_R line

and peripheral circuit.

No