1-1

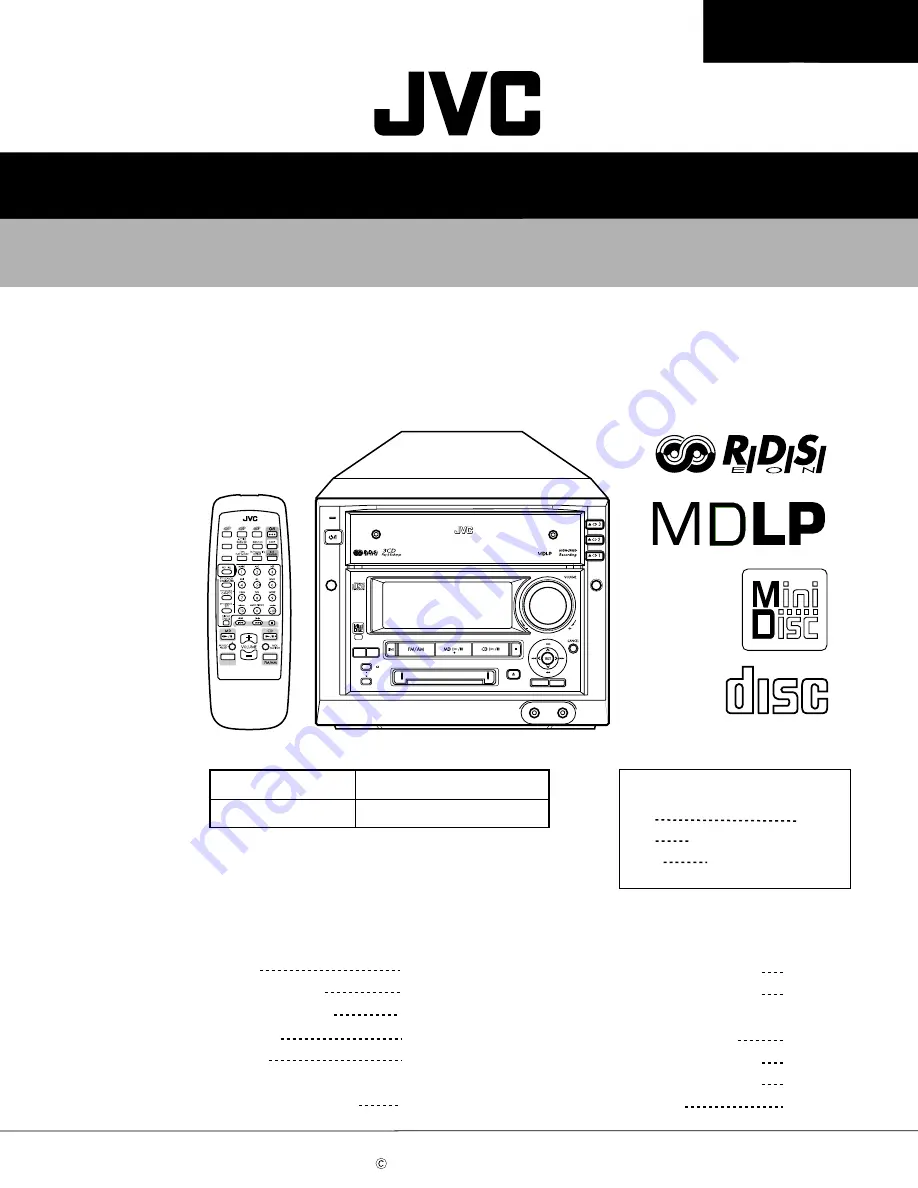

CA-MXS6MDR

SP-MXS6MD

SERVICE MANUAL

COMPACT COMPONENT MD SYSTEM

No.20876

Sep. 2000

COPYRIGHT 2000 VICTOR COMPANY OF JAPAN, LTD.

CA-MXS6MDR

SP-MXS6MD

CA-MXS6MDR

SP-MXS6MD

Contents

Safety precautions

Preventing static electricity

Important for laser products

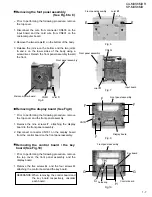

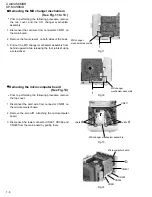

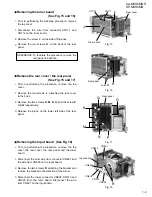

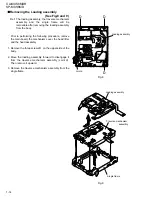

Disassembly method

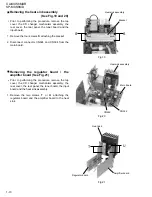

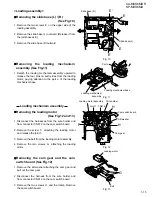

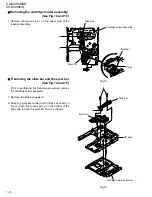

Adjustment method

Flow of functional operation

until TOC read (MD section)

Maintenance of laser pickup (MD)

Replacement of laser pickup (MD)

Flow of functional operation

until TOC read (CD section)

Maintenance of laser pickup (CD)

Replacement of laser pickup (CD)

Description of major ICs

1-2

1-4

1-5

1-6

1-31

1-37

1-38

1-38

1-39

1-40

1-40

1-41

Area Suffix

This service manual is printed on 100% recycled paper.

B

E

EN

U.K.

Continental Europe

Northern Europe

COMPACT

DIGITAL AUDIO

DISC LOADING MECHANISM

STANDBY

/ON

LONG

MODE

REC

MODE

SP/LP2/LP4

REC PAUSE

HIGH SPEED

CD MD

TITLE/EDIT

ENTER

/DEMO

PHONES

LINE 2

MENU

COMPACT COMPONENT MD SYSTEM MX-S6MDR

DISC

DIMMER

LINE

RM-SMXS6MDR

REMOTE CONTROL

LEVEL

METER

CA-MXS6MDR

SP-MXS6MD

MAIN SYSTEM

SPEAKER SYSTEM