1-15

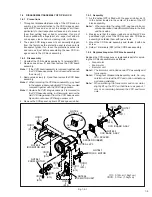

1.8 HOW TO TAKE OUT CASSETTE TAPE MANUALLY

On the occasion that the cassette tape cannot be ejected

because of an electrical trouble, remove the cassette tape

manually according to the following procedure.

Since the following procedure is just a simple measure to

remove the cassette tape, it is recommended to dismantle

cabinet parts and externally installed components as many

as possible so that the cassette tape can be removed

smoothly without force from viewpoints of workability and

reliability of the removing work.

1. Disconnect all the power supplies (battery and DC cord)

from the camera.

2. Open the monitor assembly and remove the upper cases

(2) and (1). (Refer to Fig. 1-3-2 and 1-3-3.)

3. Open the cassette cover assembly.

4. Connect 3 V DC power to the electrodes on the top of

the loading motor to side the slide deck assembly to-

wards the front side and stop the power supply when

both the pole bases are located inside the tape as their

unloading operation. At this point pay careful attention

to the tape not to get it damaged or soiled with grease,

etc., because the tape remains outside the cassette as

it is not wound completely. If the DC power is continu-

ously supplied after both the pole bases are returned

inside the tape, the mechanism enters the eject mode

and the cassette housing is accordingly lifted up. If this

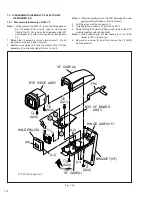

Fig. 1-8-1

(SUP)

REEL DISK

2

3

1

4

(TU)

REEL DISK

CAPSTAN

MOTOR

DRUM

LOADING

MOTOR

(DC3V)

MONITOR

ASSY

operation takes place, the part of the tape remaining out-

side is caught in the cassette lid and the tape may be

damaged partially. Be careful not to supply the DC power

excessively.

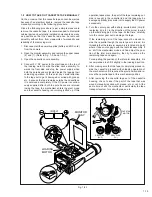

5. Turn the center gear with a sharp-pointed stick (chip IC

replacing jig, etc.) in the direction of the arrow to wind

up the remaining part of the tape. At that time, carefully

turn the center gear not to damage the tape.

If the remaining part of the tape cannot be wound in-

side the cassette though the center gear is turned, it is

thinkable that the idler arm assembly is located at a point

where it does not engage with the reel disk assembly. If

so, shift the mechanism mode and fine adjust the posi-

tion of the idler arm assembly, then try to wind up the

remaining tape once again.

For adjusting the position of the idler arm assembly, it is

recommended to shift it slightly in the loading direction.

6. After making sure that the tape is completely wound in-

side the cassette, proceed with unloading operation of

the mechanism until it reaches the eject position and re-

move the cassette tape at this mechanism position.

7. After removing the cassette tape out of the cassette

housing, check to see if the part of the tape that was

wound manually is soiled with grease, etc. or not. At the

same time, check the mechanism, particularly the tape

transport system, for soil with grease, etc.