1-2

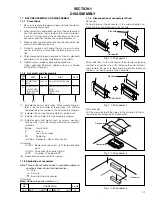

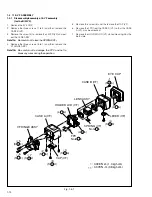

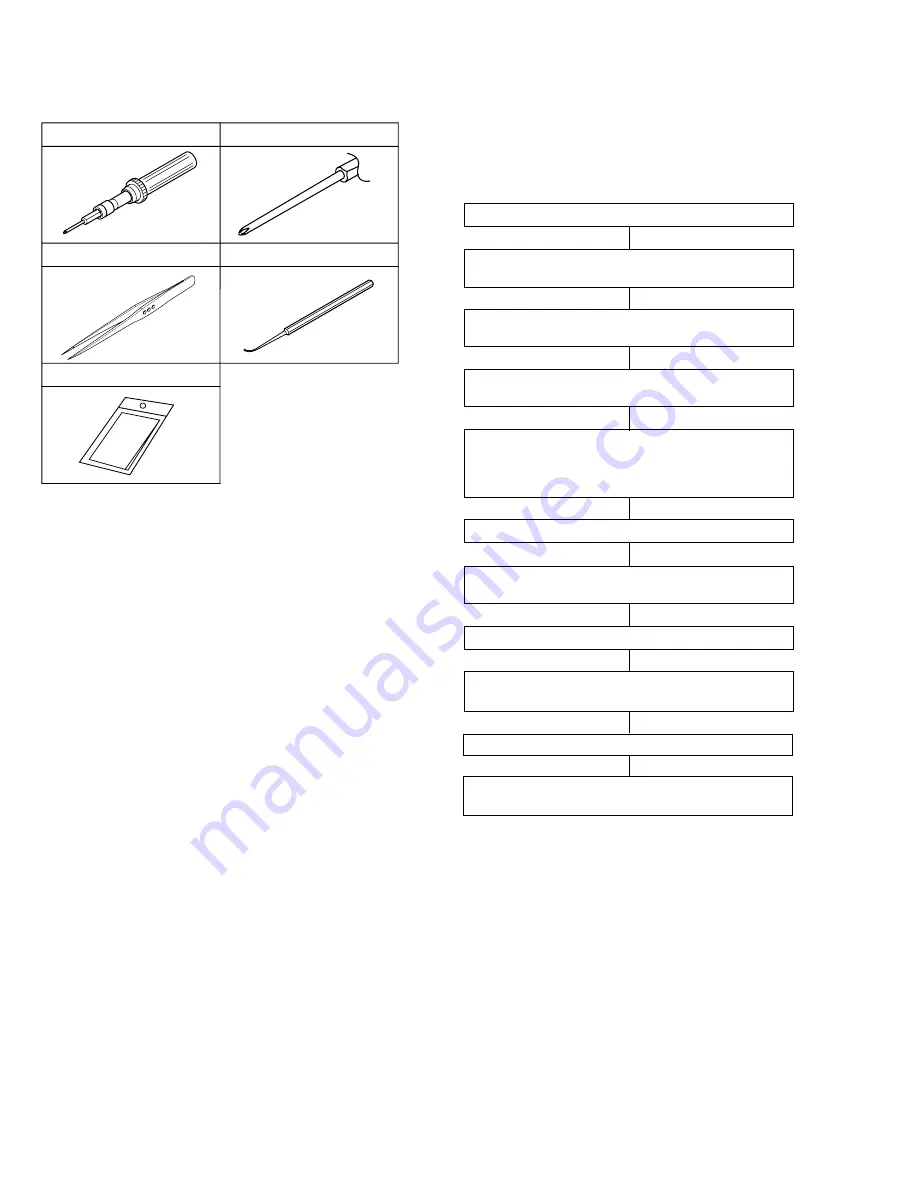

1.2 JIGS AND TOOLS REQUIRED FOR DISASSEMBLY,

ASSEMBLY AND ADJUSTMENT

1.2.1

Tools required for adjustments

1. Torque driver

Be sure to use to fastening the mechanism and exterior

parts because those parts must strictly be controlled for

tightening torque.

2. Bit

This bit is slightly longer than those set in conventional

torque drivers.

3. Tweezers

To be used for removing and installing parts and wires.

4. Chip IC replacement jig

To be used for adjustment of the camera system.

5. Cleaning cloth

Recommended cleaning cloth to wipe down the video

heads, mechanism (tape transport system), optical lens

surface.

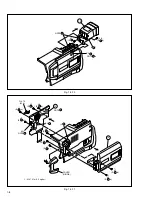

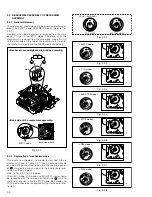

1.3 DISASSEMBLY/ASSEMBLY OF CABINET PARTS

AND BOARD ASSEMBLY

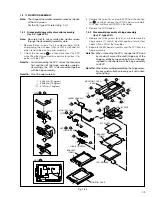

1.3.1 Disassembly flow chart

This flowchart indicates the disassembly step for the cabi-

net parts and board assembly in order to gain access to

item(s) to be serviced. When reassembling, perform the

step(s) in reverse order.

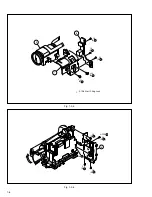

Table 1-2-1

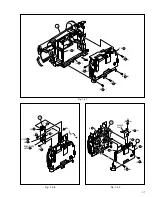

Table 1-3-1

Torque driver

YTU94088

1

Bit

YTU94088-003

2

3

Chip IC replacement jig

PTS40844-2

4

5

Cleaning cloth

KSMM-01

Tweezers

P-895

COVER(ZOOM) ASSY

UPPER CASE ASSY

(Inc.E.VF UNIT(B/W),SPEAKER/MONITOR)

FRONT COVER ASSY

(Inc. MIC)

OP BLOCK ASSY

/BRACKET(OP) ASSY

2

1

3

4

8

0

!

/

@

9

$

/

%

#

MONITOR ASSY

/MONITOR BOARD ASSY

E.VF UNIT

MAIN BOARD ASSY

/MECHANISM ASSY

JUNCTION BOARD ASSY

LOWER CASE ASSY

(Inc.ZOOM UNIT)

5

/

6

/

7

OP BLOCK ASSY/JACK BOARD ASSY/

FRAME ASSY

REAR UNIT