3-2

1.

Torque driver

Be sure to use to fastening the mechanism and exte-

rior parts because those parts must strictly be control-

led for tightening torque.

2.

Bit

This bit is slightly longer than those set in conventional

torque drivers.

3.

Tweezers

To be used for removing and installing parts and wires.

4.

Chip IC replacement jig

To be used for adjustment of the camera system.

5.

Jig connector cable

Connected to CN105 of the main board and used for

electrical adjustment, etc.

6.

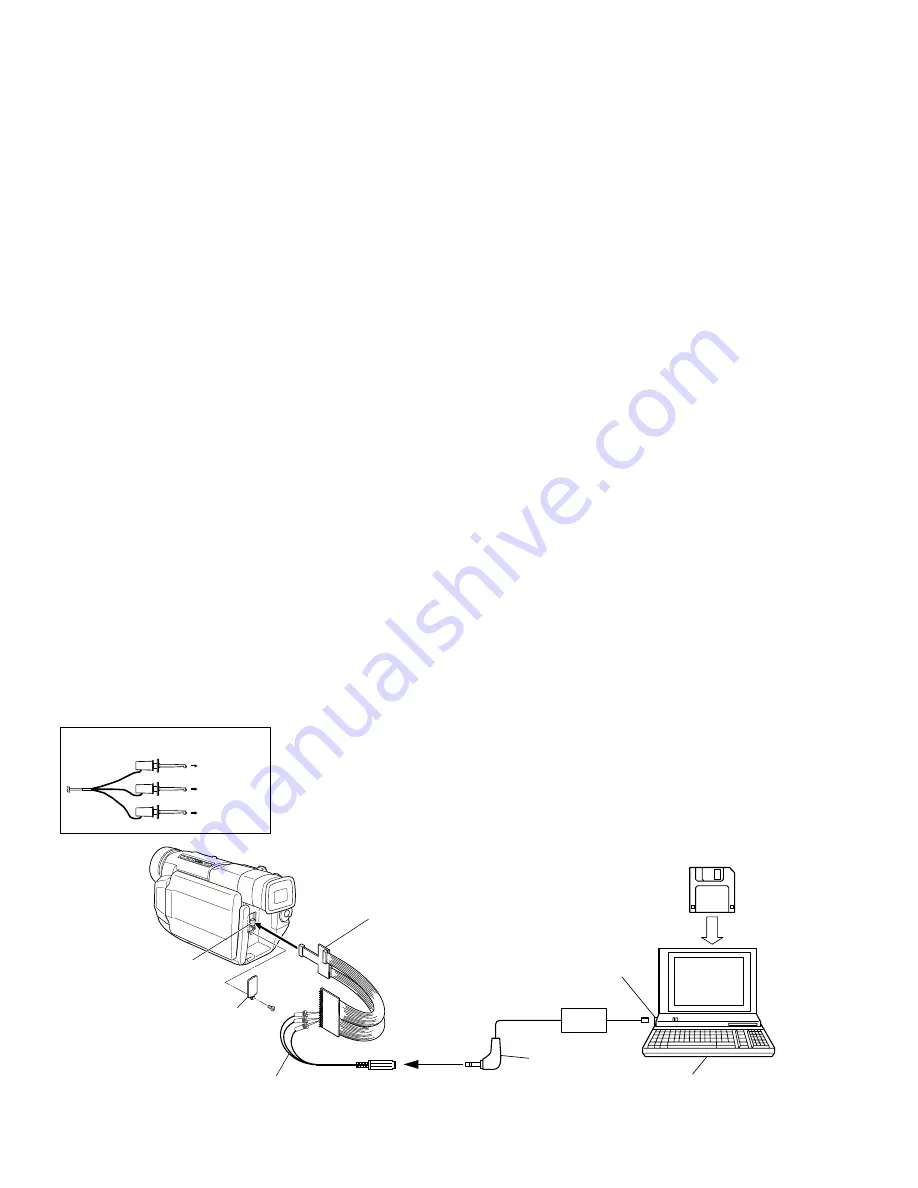

Communication cable

Connect the Communication cable between the PC

cable and Jig connector cable when performing a PC

adjustment.

7.

PC cable

To be used to connect the VideoMovie and a personal

computer with each other when a personal computer

is used for adjustment.

8.

Service support system

To be used for adjustment with a personal computer.

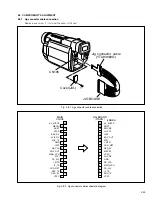

3.2 SETUP

1. Setup for electrical adjustment with personal computer.

NOTE:

Remove one screw (1) first and the cover (JIG)

next.

Fig. 3-2-1 Connection for Service support system

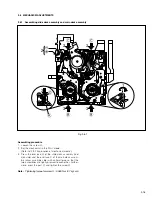

9.

Alignment tape

To be used for check and adjustment of interchange-

ability of the mechanism.

10. INF adjustment lens

To be used for adjustment of the camera system.

11. INF adjustment lens holder

To be used together with the camera stand for operat-

ing the VideoMovie in the stripped-down

condition such as the status without the exterior parts

or for using commodities that are not yet conformable

to the interchangeable ring.

12. Camera stand

To be used together with the INF adjustment lens

holder.

13. Light box assembly

To be used for adjustment of the camera system.

14. Gray scale chart (for Light box assembly)

To be used for adjustment of the camera system.

15. Color bar chart (for Light box assembly)

To be used for adjustment of the camera system.

Service Support System

RS232C

COM Port

PC CABLE

Personal Computer

MENU

RED

to CN105-8 pin

( JLIP_RX )

WHITE

BLACK

to CN105-17 pin

( JLIP_TX )

to CN105-7 pin

( GND )

COMMUNICATION CABLE JIG CONNECTOR

1

Cover(JIG)

COMMUNICATION CABLE

CN105

Jig connector cable