(No.YA092B)1-19

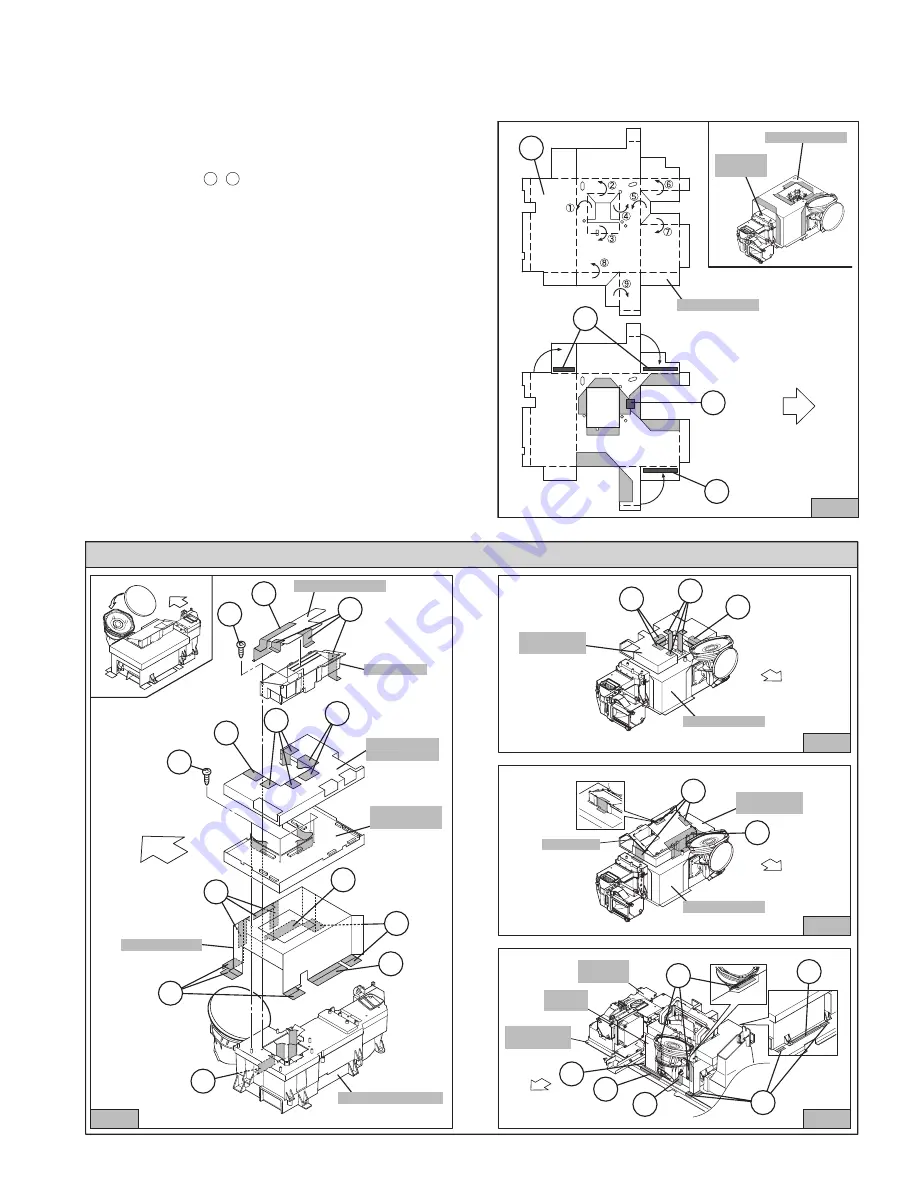

3.1.36 SHIELD PLATE ATTACHMENT PROCESS

• Take out the TOP DUCT / TOP DUCT PLATE.

• Take out the MAIN DRIVE PWB with SHIELD TOP CASE.

< Assembly >

(1) Copper film case with laminate surface to be top.

(2) Fold 9 points

as shown in

[ A ]

an arrow view Fig.1.

(3) Attach the double-faced tapes

[ B ]

as shown in Fig.1.

(4) Stick the tape

[ C ]

as shown in Fig.1.

(5) Make copper film case to be SHIELD PLATE (box-shape).

< Attachment >

(6) Install the SHIELD PLATE (box-shape).

(7) Install the MAIN DRIVE PWB.

(8) Install 4 screws

[ D ]

to MAIN DRIVE PWB.

(9) Install the SHIELD TOP CASE .

(10) Attach the shield (copper film) tapes 6 positions

[ E ]

and

[ F ]

as shown in Fig.2 and Fig.5.

(11) Install the TOP DUCT.

(12) Install 2 screws

[ G ]

as shown in Fig.5.

(13) Install the TOP DUCT PLATE as shown in Fig.5.

(14) Attach the shield (copper film) tapes 4 positions

[ H ]

and

[ I ]

as shown in Fig.3 and Fig.5.

(15) Then attach the shield (copper film) tapes 11 positions

[ J ]

[ K ]

,

[ L ]

,and

[ M ]

as shown in Fig.4 and Fig.5.

1 ~ 9

( )

<ASSEMBLY PROCESS>

Fig.1

OPTICAL

BLOCK

FRONT

SHIELD PLATE

SHIELD PLATE

(x2)

B

A

(x1)

B

(x1)

C

FRONT

FRONT

<ASSEMBLY and ATTACHMENT PROCESS>

FRONT

Fig.2

Fig.3

Fig.4

UNIT BASE

BRACKET

SHIELD

PLATE

OPTICAL

BLOCK

DUCT TOP

FRONT

FRONT

SHIELD PLATE

MAIN DRIVE

PWB

SHIELD PLATE

MAIN DRIVE

PWB

(x2)

E

(x3)

(x1)

E

(x3)

I

(x1)

H

(x3)

(x1)

(x1)

(x1)

M

J

L

K

L

F

K

OPTICAL BLOCK

TOP DUCT PLATE

MAIN DRIVE

PWB

SHIELD PLATE

TOP DUCT

SHIELD TOP

CASE

Fig.5

(x2)

(x1)

(x1)

(x1)

(x1)

(x2)

(x2)

(x1)

(x3)

(x3)

E

(x3)

E

G

(x4)

D

(x3)

L

L

K

M

J

I

H

F

K