(No.YA409)1-17

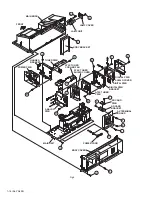

3.1.2.12 REMOVING THE LAMP COVER SW PWB (Fig.4)

• Remove the LAMP COVER.

• Remove the BODY COVER.

• Remove the BODY BRACKET.

• Remove the MAIN UNIT.

(1) Remove the 2 screws

[A]

.

(2) Remove the LAMP COVER SW BRACKET with LAMP

COVER SW PWB.

(3) Remove the 1 screw

[B]

.

(4) Remove the LAMP COVER SW PWB.

3.1.2.13 REMOVING THE TERMOSTAT (Fig.4)

• Remove the LAMP COVER.

• Remove the BODY COVER.

• Remove the BODY BRACKET.

• Remove the MAIN UNIT.

(1) Remove the 2 screws

[C]

.

(2) Remove the THERMOSTAT.

3.1.2.14 REMOVING THE LAMP FAN DUCT (Fig.4)

• Remove the LAMP COVER.

• Remove the BODY COVER.

• Remove the BODY BRACKET.

• Remove the MAIN UNIT.

• Remove the THERMOSTAT.

(1) Remove the 5 screws

[D]

.

(2) Remove the LAMP FAN DUCT.

3.1.2.15 REMOVING THE LAMP COOLING FAN -1 (Fig.4)

• Remove the LAMP COVER.

• Remove the BODY COVER.

• Remove the BODY BRACKET.

• Remove the MAIN UNIT.

• Remove the LAMP FAN DUCT.

(1) Remove the 2 screws

[E]

.

(2) Remove the COOLING FAN BRACKET by pulling

transversally.

(3) Remove the 2 screws

[F]

.

(4) Remove the LAMP COOLING FAN-1.

3.1.2.16 REMOVING THE LAMP COOLING FAN -2 (Fig.4)

• Remove the LAMP COVER.

• Remove the BODY COVER.

• Remove the BODY BRACKET.

• Remove the MAIN UNIT.

• Remove the LAMP FAN DUCT.

• Remove the COOLING FAN BRACKET.

(1) Remove the 2 screws

[G]

.

(2) Remove the LAMP COOLING FAN -2.

3.1.2.17 REMOVING THE LAMP BALLAST BLOCK (Fig.4)

• Remove the LAMP COVER.

• Remove the BODY COVER.

• Remove the BODY BRACKET.

• Remove the MAIN UNIT.

(1) Remove the 2 screws

[H]

.

(2) Remove the LAMP BALLAST UNIT.

(3) Remove the 1 screw

[J]

.

(4) Remove the LAMP BALLAST BRACKET.

3.1.2.18 REMOVING THE IRIS PWB (Fig.4)

• Remove the LAMP COVER.

• Remove the BODY COVER.

• Remove the BODY BRACKET.

• Remove the MAIN UNIT.

(1) Remove the 2 screws

[K]

.

(2) Remove the IRIS PWB.

3.1.2.19 REMOVING THE REMOCON PWB(Fig.4)

• Remove the LAMP COVER.

• Remove the BODY COVER.

• Remove the BODY BRACKET.

• Remove the MAIN UNIT.

(1) Remove the 1 screw

[L]

.

(2) Remove the REMOCON PWB.

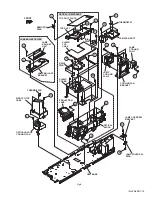

3.1.2.20 REMOVING THE OPTICAL / DRIVE ASS'Y (Fig.4)

• Remove the LAMP COVER.

• Remove the BODY COVER.

• Remove the BODY BRACKET.

• Remove the MAIN UNIT.

• Remove the LAMP FAN DUCT.

(1) Remove the 7 screws

[M]

, 6 screws

[N]

and 1 screw

[P]

.

(2) Remove the OPTICAL / DRIVE ASS'Y.

• OPTICAL BLOCK (D-ILA device, PBS, Field lens,

Integrater, Mirror etc.)

• PROJECTION LENS

• Optical base

• DRIVE PWB

• IRIS PWB

• TOP DUCT

• SHIELD COVER

NOTE :

• The OPTICAL / DRIVE ASS'Y contains precision optical

components.

• Handle carefully and avoid imparting strong shock.

• OPTICAL / DRIVE ASS'Y construction

• When not performing repair work, attach the cap on the lens

to preventing dust from covering.

• When mounting to the set, make sure the front of the lens

side is in contact with the cushion on the body side.

• Do not leave the OPTICAL / DRIVE ASS'Y removed for long

time to prevent soiling from dust.