(No.82933)1-29

Fig.3-3-2b

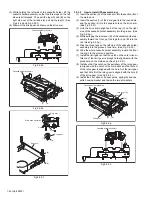

3.3.3 Height and tilt of the A/C head

Note:

• Set a temporary level of the height of the A/C head in ad-

vance to make the adjustment easier after the A/C head has

been replaced. (See Fig.3-2-6c.)

(1) Play back the alignment tape (A).

(2) Apply the external trigger signal to D.FF (E), to observe the

AUDIO OUT waveform and Control pulse waveform at the

measuring points (D1) and (D2) in the ALT mode.

(3) Set the VCR to the manual tracking mode.

(4) Adjust the AUDIO OUT waveform and Control pulse wave-

form by turning the screws (1), (2) and (3) little by little until

both waveforms reach maximum. The screw (1) and (3) are

for adjustment of tilt and the screw (2) for azimuth.

Fig.3-3-3a

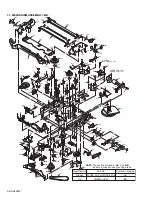

3.3.4 A/C head phase (X-value)

(1) Play back the alignment tape (A1).

(2) Apply the external trigger signal to D.FF (E), to observe the

V.PB FM waveform at the measuring point (D).

(3) Set the VCR to the manual tracking mode.

(4) Loosen the screws (4) and (5), then set the A/C head posi-

tioning tool to the innermost projected part of the A/C head.

(See Fig. 3-3-4a.)

(5) Turn the A/C head positioning tool fully toward the capstan.

Then turn it back gradually toward the drum and stop on the

second peak point position of the V.PB FM waveform out-

put level. Then tighten the screws (4) and (5).

(6) Perform the tracking operation and make sure that the

V.PB FM waveform is at its maximum.

If it is not at maximum, loosen the screws (4) and (5), and

turn the A/C head positioning tool to bring the A/C head to

a position, around where the waveform reaches its maxi-

mum for the first time. Then tighten the screws (4) and (5).

Note:

•

After adjusting, always perform the confirmation and re-

adjustment of the item 3.3.5.

Fig.3-3-4a

Fig.3-3-4b

3.3.5 Standard tracking preset

(1) Play back the alignment tape (A).

(2) Apply the external trigger signal to D.FF (E), to observe the

V.PB FM waveform at the measuring point (D).

(3) Confirm that the automatic tracking operation is completed.

(4) Set the VCR to the Auto adjust mode by transmitting the

code (F) twice from the Jig RCU. When the VCR enters the

stop mode, the adjustment is completed.

(5) If the VCR enters the eject mode, perform adjustment for

the audio control head phase (X-value) again.

Signal

(A)

• Alignment tape(SP, stairstep, NTSC) [MHP]

Mode

(B)

• PB

Equipment

(C)

• Oscilloscope

Measuring point (D1)

(D2)

• AUDIO OUT terminal

• TP4001 (CTL. P)

External trigger (E)

• TP111 (D.FF)

Adjustment part (F)

• A/C head [Mechanism assembly]

Specified value (G)

• Maximum waveform

Signal

(A1) • Alignment tape(SP, stairstep, NTSC) [MHP]

Mode

(B)

• PB

Equipment

(C)

• Oscilloscope

Measuring point (D)

• TP106 (PB. FM)

External trigger (E)

• TP111 (D.FF)

Adjustment part (F)

• A/C head base [Mechanism assembly]

Specified value (G)

• Maximum V.PB FM waveform

Adjustment tool (H)

• A/C head positioning tool [PTU94010]

(a) Guide roller

(b) Guide pole

Improper

Proper

Head base

A/C head

AUDIO OUT

CTL. P

(1)

(2)

(3)

Signal

(A)

• Alignment tape(EP, stairstep, NTSC) [MHP-L]

Mode

(B)

• PB

Auto adjust

Equipment

(C)

• Oscilloscope

Measuring point (D)

• TP106 (PB. FM)

External trigger (E)

• TP111 (D.FF)

Adjustment part (F)

• Jig RCU: Code “50”

Specified value (G)

• STOP mode

(Maximum V.PB FM waveform)

Adjustment tool (H)

• Jig RCU [PTU94023B]

A/C head positioning tool

Screw (4)

Screw (5)

Toward the drum

Toward the capstan

To the drum

A/C head

To the capstan

Head base

Alignment tape

[SP, stairstep]

played with the

SP head

Alignment tape

[EP(LP), stairstep]

played with the

EP(LP) head

Drum side

Control head position

Capstan side

X-value adjustment point

Maximum

Waveform output