(No.82933)1-9

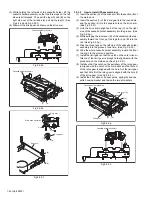

2.4 Service position

This unit has been designed so that the Mechanism and Main

board assemblies can be removed together from the chassis as-

sembly. Before diagnosing or servicing the circuit boards, take

out the major parts from the chassis assembly.

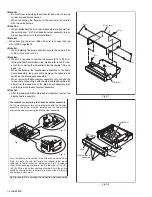

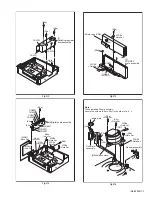

2.4.1 How to set the “Service position”

(1) Refer to the disassembly procedure and perform the disas-

sembly of the major parts before removing the PRE/REC

board assembly.

(2) Remove the screws attaching the mechanism assembly

with the chassis assembly. Remove the screws attaching

the board assembly, if necessary.

(3) Remove the combined Mechanism and Main board assem-

blies.

(4) Connect the wires and connectors of the major parts that

have been removed in step (1). (Refer to Fig.2-4-1a.)

(5) Place the combined Mechanism and Main board assem-

blies upside down.

(6) Insert the power cord plug into the power outlet and then-

proceed with the diagnostics and servicing of the board as-

sembly.

Notes:

•

Before inserting the power cord plug into the power out-

let, make sure that none of the electrical parts are able

to short-circuit between the workbench and the board

assembly.

•

For the disassembly procedure of the major parts and

details of the precautions to be taken, see “2.3 Disas-

sembly/assembly method”.

•

If there are wire connections from the Main board and

Mechanism assemblies to the other major parts, besure

to remove them ( including wires connected to the major

parts ) first before performing step (2).

•

When carrying out diagnosis and repair of the Main

board assembly in the “Service position”, be sure to

ground both the Main board and Mechanism assem-

blies. If they are improperly grounded, there may

benoise on the playback picture or FDP counter display-

may move even when the mechanism is kept in an inop-

erative status.

•

In order to diagnose the playback or recording of the-

cassette tape, set the Mechanism assembly to the re-

quired mode before placing it upside down. If the

mechanism mode is changed (including ejection) while

it is in an upside down position the tape inside may be

damaged.

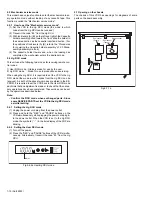

2.4.2 Precautions for cassette loading in the “Service posi-

tion”

The REC safety board assembly detects cassette loading as well

as cassette tabs. Therefore, after the assembly has been re-

moved in the “Service position”, it is required to set the switch

manually on the REC safety board assembly when a cassette is

loaded.

2.4.3 Cassette loading and ejection methods in the “Ser-

vice position”

(1) Insert a cassette halfway in the Cassette holder assembly.

(2) Set the switch on the REC safety board assembly to on (by

pressing the switch).

(3) As soon as the cassette starts to be loaded, set the switch

on the REC safety board assembly to off (by releasing the

switch).

(4) Now the desired operation (recording, playback, fast for-

ward, rewind, etc.) is possible in this status.

(5) The switch on the REC safety board assembly does

nothave to be operated when ejecting a tape. But be sure

to turn the set to the normal position before ejecting the

tape.

Note:

• In the “Service position”, the cassette tabs cannot be detect-

ed and recording becomes possible even with a cassette

with broken tabs such as the alignment tape. Be verycareful

not to erase important tapes.

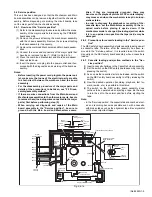

Fig.2-4-1a

Jack board

assembly

Display board assembly

CP4001

CP3002

Main board assembly

Switching regulator

board assembly

TP4001

CTL P

TP2253

A.PB FM

TP111

D.FF

TP106

PB FM

TP2254

A.REC FM

VR2251

FMA

REC

LEVEL

TP501

Y TO SE

Digital

board assembly

PRE/REC

board assembly

CN7005

CN7002

REC Safety

board assembly

Terminal sub board assembly

CN3009

CN7017

CN7191

CN8001

CN8002

TO CN8002

TO CN8001

CN9001

CN9301

CN8005

CN8003

CN8004

CN8801

CN901

CN401

CN402

CN3008

CN5603

CN601

CN602

CN7104

CN7101

CN7102

TP622 TP612

TP621 TP602 T611

TP611

REC_LEVEL1

TP621

PB_DATA1

TP602

A/HS2_FF

TP622

PB_DATA2

TP612

REC_LEVEL2