3-1

SECTION 3

ELECTRICAL ADJUSTMENT

3.1 PRECAUTION

The following adjustment procedures are not only necessary

after replacement of consumable mechanical parts or board

assemblies, but are also provided as references to be re-

ferred to when servicing the electrical circuitry.

In case of trouble with the electrical circuitry, always begin a

service by identifying the defective points by using the meas-

uring instruments as described in the following electrical ad-

justment procedures. After this, proceed to the repair, replace-

ment and/or adjustment. If the required measuring instruments

are not available in the field, do not change the adjustment

parts (variable resistor, etc.) carelessly.

3.1.1 Required test equipments

• Color (colour) television or monitor

• Oscilloscope:

wide-band, dual-trace, triggered delayed

sweep

• Frequency counter

• Signal generator: RF / IF sweep / marker

• Signal generator: stairstep, color (colour) bar [PAL]

• Recording tape

• Digit-key remote controller(provided)

3.1.2

Required adjustment tools

3.1.3 Color (colour) bar signal,Color (colour) bar pattern

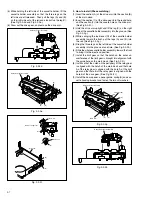

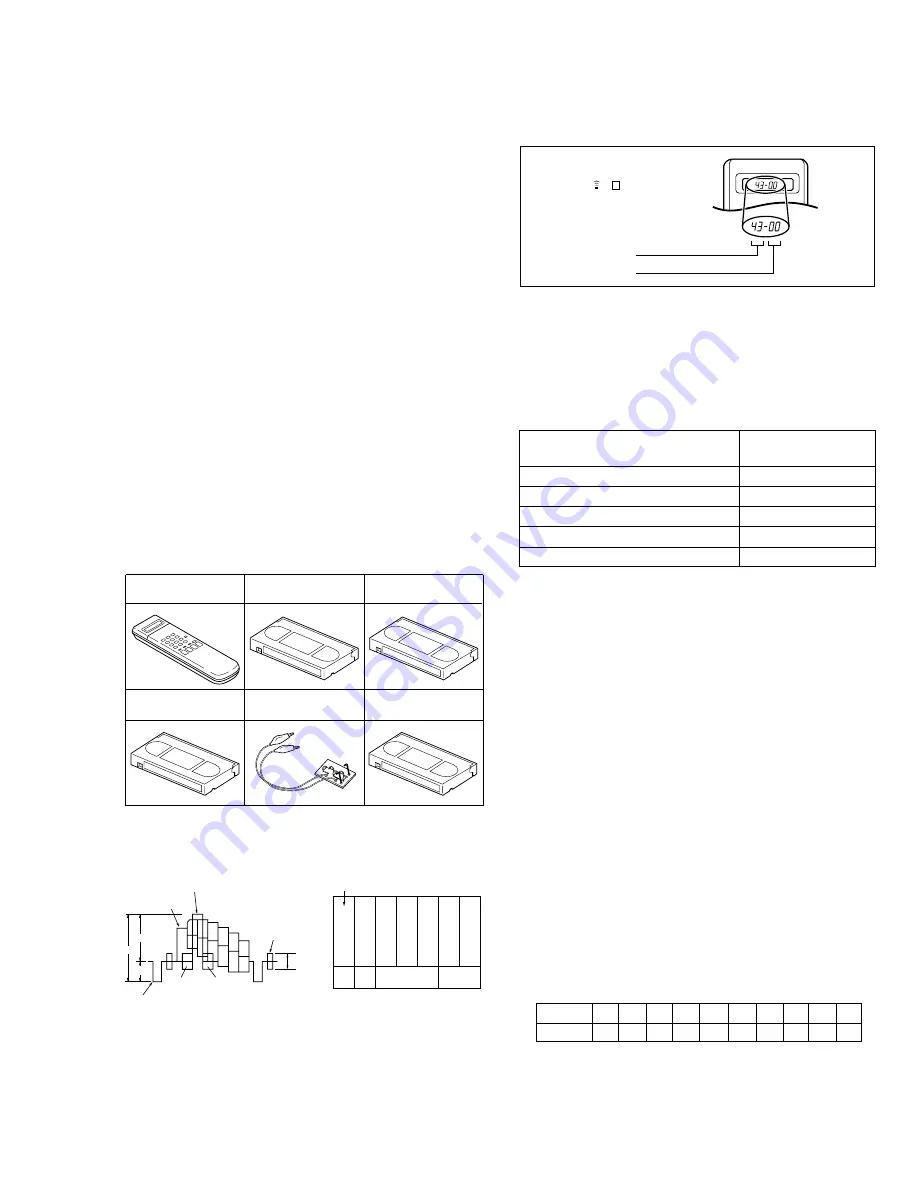

Fig. 3-1-4a Jig RCU [PTU94023B]

3.1.4 Switch settings and standard precautions

The SW settings of the VCR and the standard precautions

for the electrical adjustments are as follows.

• When using the Jig RCU, set its custom code to match

the custom code of the VCR.

• Set the switches as shown below unless otherwise

specified on the relevant adjustment chart. The

switches that are not listed below can be set as de-

sired.

If the VCR is not equipped with the functions detailed

below, setup is not required.

AUTO PICTURE/VIDEO CALIBRATION/

OFF

B.E.S.T./D.S.P.C.

PICTURE CONTROL/SMART PICTURE

NORMAL/NATURAL

VIDEO STABILIZER

OFF

TBC

ON

Digital 3R

ON

VIDEO NAVIGATION/TAPE MANAGER

OFF

• Unless otherwise specified, all measuring points and

adjustment parts are located on the Main board.

• In the Signal column of the adjustment chart, “Ext. S-

input” means the Y/C separated video signal and “Ext.

input” means the composite video signal input.

Jig RCU

PTU94023B

Alignment tape

(SP, stairstep, PAL)

MHPE

Alignment tape

(LP, stairstep, PAL)

MHPE-L

LPF

PTU93006

Alignment tape

(SP stairstep, NTSC)

MHP

Alignment tape

(S-VHS, SP/LP, color (colour) bar)

MH-2H

INITIAL MODE

DATA CODE

CUSTOM CODE

43: A

CODE

53: B

CODE

6F: C

CODE

7F: D

CODE

[Data transmitting method]

Depress the “ ” ( 3 ) button

after the data code is set.

Jig RCU

3.1.5 EVR Adjustment

Some of the electrical adjustments require the adjustment

performed by the EVR system. The Main board assembly

have EEPROMs for storing the EVR adjustment data and

user setups.

Notes:

• In the EVR adjustment mode, the value is varied with

the channel buttons (+, –). The adjusted data is stored

when the setting mode changes (from PB to STOP,

when the tape speed is changed, etc.). Take care to

identify the current mode of each adjustment item

when making an adjustment.

• When changing the address setting in the EVR adjust-

ment mode, use the Jig RCU or the remote controller

having numeric keypad with which a numeric code can

be directly input.

The remote control code of the Jig RCU corresponds

to each of the digit keys on the remote controller as

follows.

• As the counter indication and remaining tape indica-

tion are not displayed FDP during the EVR adjustment

mode, check them on the TV monitor screen.

• When performing the EVR adjustment, confirm that the

FDP indication is changed to the EVR mode, as shown

below.

Digit-key

0

1

2

3

4

5

6

7

8

9

Code

20 21

22 23

24

25

26

27 28 29

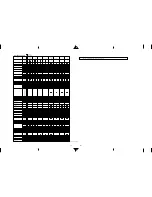

(75%)

White(75%)

0.7 V

0.3 V

Horizontal sync

V

U

1V

White(100%)

Yellow

Cyan

Green

Magenta

Red

Blue

Burst

0.3 V

V(R-Y)

U(B-Y)

White

Yellow

Cyan

Green

Magenta

Red

Blue

U

Black

White

100%

V

s

Colour bar signal [PAL]

s

Colour bar pattern [PAL]