3-3

(1) Observe the Y OUT waveform at the measuring point (D).

(2) Record the signal (A2) in the mode (B1), and play back

the recorded signal.

(3) Press the channel buttons (+, –) simultaneously to enter

the manual tracking mode. This also brings tracking to

the center (centre).

(4) Set the VCR to the EVR mode by transmitting the code

(F1) from the Jig RCU.

(5) Set the EVR address to (F2) by pressing the button of

the digit-key remote controller.

(6) Adjust with the channel buttons (+, –) on the VCR (or on

the remote controller) so that the Y level of the Y OUT

waveform becomes the specified value (G).

3.3.3 PB Y level (S-VHS / VHS)

Signal

(A1)

•

Ext. input

(A2)

•

Color (colour) bar signal [PAL]

Mode

(B1)

•

S-VHS SP

(B2)

•

VHS SP

Equipment

(C)

•

Oscilloscope

Measuring point

(D)

•

Y OUT terminal (75

Ø

terminated)

EVR mode

(F1)

•

Jig RCU: Code “57”

EVR address

(F2)

•

A:11 (Press remote controller

“1” key twice)

Specified value

(G)

•

1.00 ± 0.03 Vp-p

Adjustment tool

(H)

•

Jig RCU [PTU94023B]

•

Digit-key remote controller

Signal

(A1)

•

Ext. input

(A2)

•

Color (colour) bar signal [PAL]

Mode

(B)

•

EE

Equipment

(C)

•

Oscilloscope

Measuring point

(D)

•

Y OUT terminal (75

Ø

terminated)

EVR mode

(F1)

•

Jig RCU: Code “57”

EVR address

(F2)

•

A:11 (Press remote controller “1” key twice)

Specified value

(G)

•

1.00 ± 0.03 Vp-p

Adjustment tool

(H)

•

Jig RCU [PTU94023B]

• Digit-key remote controller

(1) Observe the Y OUT waveform at the measuring point (D).

(2) Set the VCR to the EVR mode by transmitting the code

(F1) from the Jig RCU.

(3) Set the EVR address to (F2) by pressing the button of

the digit-key remote controller.

(4) Adjust with the channel buttons (+, –) on the VCR (or on

the remote controller) so that the Y level of the Y OUT

waveform becomes the specified value (G).

(5) Release the EVR mode of the VCR by transmitting the

code (F1) from the Jig RCU again. (When the EVR mode

is released, the adjusted data is memorized.)

Fig. 3-3-2a EE Y level

H. rate

Specified

value (G)

3.3.2 EE Y level

Fig. 3-3-3a PB Y level

H. rate

Specified

value (G)

(7) Release the EVR mode of the VCR by transmitting the

code (F1) from the Jig RCU again. (When the EVR mode

is released, the adjusted data is memorized.)

(8) Repeat steps (2) to (7) in the mode (B2).

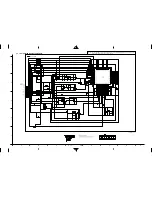

Fig. 3-3-4a LPF

1 k

Ø

39

µ

H

180

µ

H

120 pF

180 pF

PB. FM

629 [kHz]

PB COLOR

(PB COLOUR)

3.3.4 REC color (colour) level

Signal

(A1)

•

Alignment tape(S-VHS, SP/LP, Color(colour)

bar) [MH-2H]

(A2)

•

Ext. input

(A3)

•

Color (colour) bar signal [PAL]

Mode

(B1)

•

S-VHS SP

(B2)

•

S-VHS LP

Equipment

(C)

•

Oscilloscope

Measuring point

(D1)

•

TP106 (PB FM)

(D2)

•

PB color (colour) output of the LPF

External trigger

(E)

•

TP111 (D.FF)

EVR mode

(F1)

•

Jig RCU: Code “57”

EVR address

(F2)

•

A:02 (Press remote controller

“0” and “2” keys)

Specified value

(G)

•

SP: “B” x 125 ± 5%

•

LP: “B” x 125 ± 5%

Adjustment tool

(H1)

•

Jig RCU [PTU94023B]

(H2)

•

Digit-key remote controller

(H3)

• LPF [PTU93006] (See Fig. 3-3-4a.)

(1) Connect the adjustment tool (H3) to the measuring point (D1).

(2) Apply the external trigger signal to D.FF (E) to observe the

PB color (colour) waveform at the measuring point (D2).

(3) Play back the signal (A3) in the mode (B1) of the align-

ment tape (A1).

(4) Press the channel buttons (+, –) simultaneously to enter

the manual tracking mode. This also brings tracking to

the center (centre).

(5) Adjust tracking by pressing the channel buttons (+, –) so

that the PB color (colour) waveform becomes maximum.

Make a note of the higher PB color (colour) level as “B”

at this time.

(6) Record the signal (A3) in the mode (B1), and play back

the recorded signal.

(7) Set the VCR to the EVR mode by transmitting the code

(F1) from the Jig RCU.

(8) Set the EVR address to (F2) by pressing the button of

the digit-key remote controller.