3-2

3.2 Mechanism compatibility adjustment

Notes:

• Although compatibility adjustment is very important, it is not

necessary to perform this as part of the normal servicing

work. It will be required when you have replaced the A/C head,

drum assembly or any part of the tape transport system.

• To prevent damaging the alignment tape in the compatibility

adjustment, prepare a cassette tape (for self-recording/play-

back), perform a test on it by transporting it and making sure

that the tape is not bent by the tape transport mechanisms

such as in the guide rollers.(See Fig.3-2-2a)

3.2.1 Tension pole position

Signal

(A)

•

Back tension cassette gauge

[PUJ48076-2]

Mode

(B1)

•

Play back position

(B2)

•

Eject end

Adjustment part

(F)

•

Adjust pin [Mechansim assembly]

Specified value

(G)

•

25 - 51 gf•cm (2.45 – 5

×

10

-3

Nm]

Notes:

•

This adjustment must be performed every time the tension

band is replaced.

(1) Play back the back tension cassette gauge (A).

(2) Check that the indicated value on the left side gauge is

within the specified value (G).

(3) If the indicated value is not within the specified value (G),

perform the adjustment in a following procedure.(See

Fig.3-2-1a.)

1) Remove the top frame, cassette holder and side

frames (L/R) all together. (See “section 2 mecha-

nism”.)

2) Rotate the loading motor gear to move the control plate

so that the triangular stamping to the left of the “P”

stamping is aligned with the stamping (a) on the main

deck. This positioning is mode (B1).

3) Adjust by turning the adjustment pin so that the tip of

the tension arm is aligned with the stamping (b) on

the main deck.

4) Rotate the reel disk (S) by about one turn clockwise

and make sure that the round hole of the adjustment

pin is located in the “OK” range.

If it is outside this range, restart the adjustment from

the beginning.

After completion of the adjustment, rotate the loading gear

motor to return it to the mode (B2) position.

3.2.2 FM waveform linearity

Signal

(A1)

•

Alignment tape(SP, stairstep, PAL) [MHPE]

(A2)

•

Alignment tape(LP, stairstep, PAL) [MHPE-L]

Mode

(B)

•

PB

Equipment

(C)

•

Oscilloscope

Measuring point

(D)

•

TP106 (PB. FM)

External trigger

(E)

•

TP111 (D.FF)

Adjustment part

(F)

•

Guide roller [Mechanism assembly]

Specified value

(G)

•

Flat V.PB FM waveform

Adjustment tool

(H)

•

Roller driver [PTU94002]

OK

NG

ADJUST PIN

TENSION ARM

Stamping(b)

Stamping(a)

CONTROL PLATE

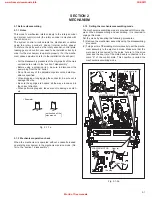

Fig. 3-2-1a

(1) Play back the alignment tape (A1).

(2) Apply the external trigger signal to D.FF (E), to observe

the V.PB FM waveform at the measuring point (D).

(3) Set the VCR to the manual tracking mode.

(4) Make sure that there is no significant level drop of the V.PB

FM waveform caused by the tracking operation, with its

generally parallel and linear variation ensured. Perform the

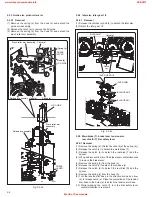

following adjustments when required. (See Fig. 3-2-2b.)

(5) Reduce the V.PB FM waveform by the tracking opera-

tion. If a drop in level is found on the left side, turn the

guide roller of the pole base assembly (supply side) with

the roller driver to make the V.PB FM waveform linear.

If a drop in level is on the right side, likewise turn the guide

roller of the pole base assembly (take-up side) with the

roller driver to make it linear. (See Fig. 3-2-2b.)

(6) Make sure that the V.PB FM waveform varies in parallel

and linearly with the tracking operation again. When re-

quired, perform fine-adjustment of the guide roller of the

pole base assembly (supply or take-up side).

(7) Unload the cassette tape once, play back the alignment

tape (A1) again and confirm the V.PB FM waveform.

(8) After adjustment, confirm that the tape wrinkling does not

occur at the roller upper or lower limits. (See Fig. 3-2-2a.)

[Perform adjustment step (9) only for the models

equipped with SP mode and EP (or LP) mode.]

(9) Repeat steps (1) to (8) by using the alignment tape (A2).

(a) GUIDE ROLLER

(b) GUIDE POLE

Improper

Proper

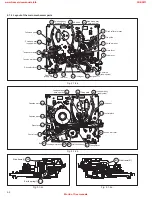

Fig. 3-2-2a

www.freeservicemanuals.info

25/8/2013

World of free manuals