1-10

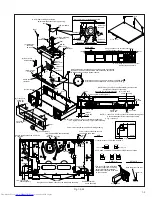

Tape transport

Drum assembly

A/C head

Pinch roller arm assembly

Full erase head

Tension arm assembly

Capstan motor (Shaft)

Guide arm assembly

Capstan motor

Capstan brake assembly

Main brake assembly

Belt (Capstan)

Loading motor

Clutch unit

Worm gear

Control plate

Rotary encoder

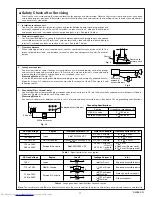

C,X

C,X

C

C

C

C

C

X

X

C,X

C

C

C

C

C

X

X

X

X

X

X

X

X

X

Operation hours

1000H

2000H

Drive

System

Parts name

C : Cleaning

X : Inspection or Replacement if necessary

Other

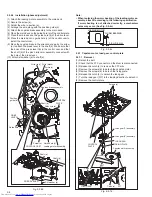

1.7 Maintenance and inspection

1.7.1

Cleaning

Regular cleaning of the transport system parts is desirable but

practically impossible. So make it a rule to carry out cleaning

of the tape transport system whenever the machine is serv-

iced.

When the video head, tape guide and/or brush get soiled, the

playback picture may appear inferior or at worst disappear, re-

sulting in possible tape damage.

Note:

•

Absolutely avoid sweeping the upper drum vertically as

this will cause damage to the video head.

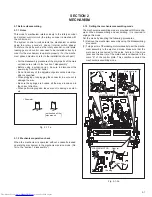

(1) When cleaning the upper drum (especially the video head),

soak a piece of closely woven cloth with alcohol and while

holding the cloth onto the upper drum by the fingers, turn

the upper drum counterclockwise.

(2) To clean the parts of the tape transport system other than

the upper drum, use a piece of closely woven cloth or a

cotton swab soaked with alcohol.

(3) After cleaning, make sure that the cleaned parts are com-

pletely dry before using the cassette tape.

Fig. 1-7-1a

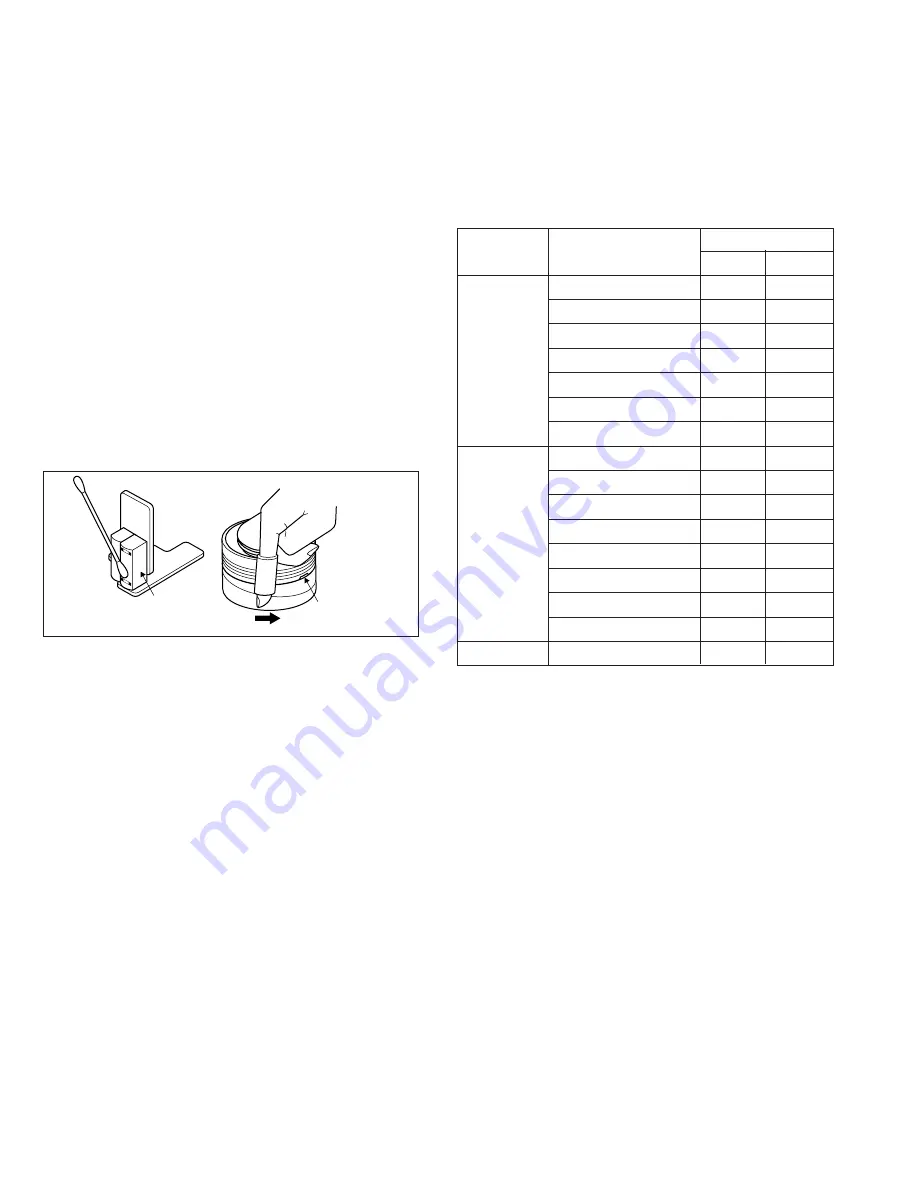

1.7.2

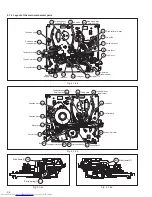

Lubrication

With no need for periodical lubrication, you have only to lubri-

cate new parts after replacement. If any oil or grease on con-

tact parts is soiled, wipe it off and newly lubricate the parts.

Note:

•

See the “mechanism assembly” diagram of the “parts list”

for the lubricating or greasing spots, and for the types of

oil or grease to be used.

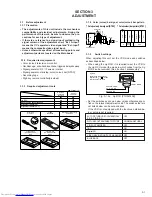

1.7.3

Suggested servicing schedule for main components

The following table indicates the suggested period for such

service measures as cleaning, lubrication and replacement. In

practice, the indicated periods will vary widely according to en-

vironmental and usage conditions. However, the indicated com-

ponents should be inspected when a set is brought for service

and the maintenance work performed if necessary. Also note

that rubber parts may deform in time, even if the set is not used.

Video heads

A/C head