3-2

3.1.7

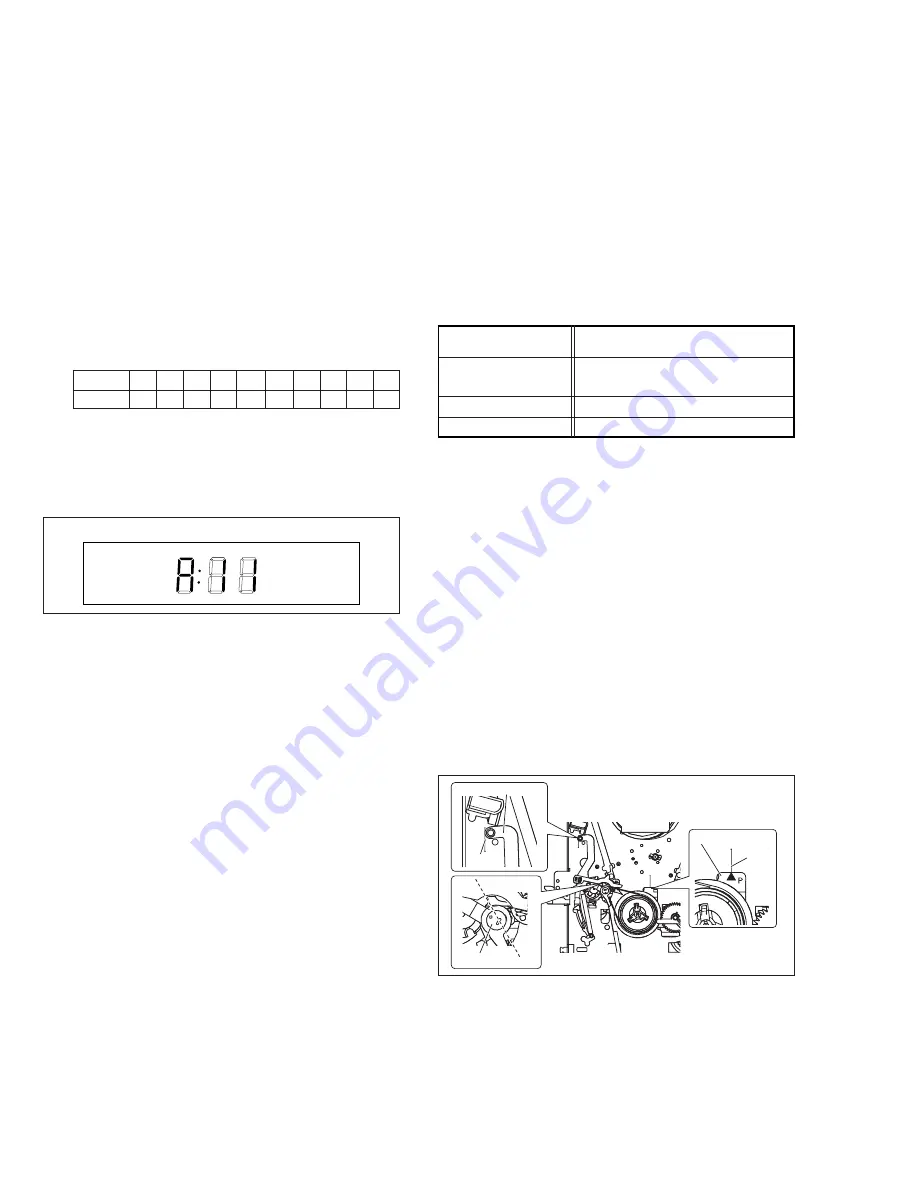

EVR adjustment

Some of the adjustments require the adjustment performed

by the EVR system. The main unit have EEPROMs for stor-

ing the EVR adjustment data and user setups.

Notes:

• In the EVR adjustment mode, the value is varied with

the channel buttons (+, –). The adjusted data is stored

when the setting mode changes (from PB to STOP,

when the tape speed is changed, etc.). Take care to

identify the current mode of each adjustment item

when making an adjustment.

• When changing the address setting in the EVR adjust-

ment mode, use the Jig RCU or the remote controller

having numeric keypad with which a numeric code can

be directly input.

The remote control code of the Jig RCU corresponds

to each of the digit keys on the remote controller as

follows.

• As the counter indication and remaining tape indica-

tion are not displayed FDP during the EVR adjustment

mode, check them on the TV monitor screen.

• When performing the EVR adjustment, confirm that the

FDP indication is changed to the EVR mode, as shown

below.

Digit-key

0

1

2

3

4

5

6

7

8

9

Code

20 21

22 23

24

25

26

27 28 29

FDP

Fig. 3-1-7a EVR mode

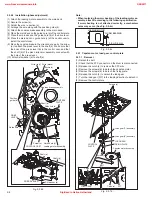

3.2 Mechanism compatibility adjustment

Notes:

• Although compatibility adjustment is very important, it is not

necessary to perform this as part of the normal servicing

work. It will be required when you have replaced the A/C head,

drum assembly or any part of the tape transport system.

• To prevent damaging the alignment tape in the compatibility

adjustment, prepare a cassette tape (for self-recording/play-

back), perform a test on it by transporting it and making sure

that the tape is not bent by the tape transport mechanisms

such as in the guide rollers.(See Fig.3-2-2a)

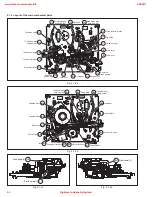

3.2.1 Tension pole position

Signal

(A)

•

Back tension cassette gauge

[PUJ48076-2]

Mode

(B1)

•

Play back position

(B2)

•

Eject end

Adjustment part

(F)

•

Adjust pin [Mechansim assembly]

Specified value

(G)

•

25 - 51 gf•cm (2.45 – 5

×

10

-3

Nm]

Notes:

•

This adjustment must be performed every time the tension

band is replaced.

(1) Play back the back tension cassette gauge (A).

(2) Check that the indicated value on the left side gauge is

within the specified value (G).

(3) If the indicated value is not within the specified value (G),

perform the adjustment in a following procedure.(See

Fig.3-2-1a.)

1) Remove the top frame, cassette holder and side

frames (L/R) all together. (See “section 2 mecha-

nism”.)

2) Rotate the loading motor gear to move the control plate

so that the triangular stamping to the left of the “P”

stamping is aligned with the stamping (a) on the main

deck. This positioning is mode (B1).

3) Adjust by turning the adjustment pin so that the tip of

the tension arm is aligned with the stamping (b) on

the main deck.

4) Rotate the reel disk (S) by about one turn clockwise

and make sure that the round hole of the adjustment

pin is located in the “OK” range.

If it is outside this range, restart the adjustment from

the beginning.

After completion of the adjustment, rotate the loading gear

motor to return it to the mode (B2) position.

OK

NG

ADJUST PIN

TENSION ARM

Stamping(b)

Stamping(a)

CONTROL PLATE

Fig. 3-2-1a

www.freeservicemanuals.info

3/28/2017

Digitized in Heiloo Netherland