KS-F171

(No.49774)1-15

Mechanism adjustment section

Item

Adjusting & Confirmation Methods

Adjust

Std. Value

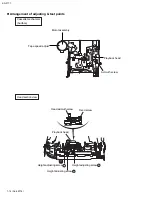

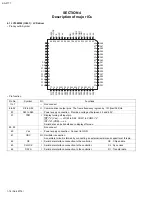

Head shield

Head shield

The head is at low position

during FWD.

The head is at height position

during REV.

A Line

B Line

Phase

screw (c)

screw (a)

screw (b)

Head azimuth

screw

Fixed screw

0

°

45

°

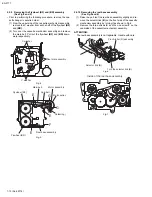

1. Head azimuth

2. Tape Speed and

Wow & Flutter

3. Playback

Frequency

response

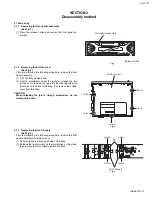

"Head Height Adjustment"

Note

Adjust the azimuth directly. When you adjust the height

using a mirror tape, remove the cassette housing from the

mechanism chassis.

After installing the cassette housing, perform the azimuth

adjustment.

1. Load the mirror tape ( SCC-1659 ). Adjust with height

adjustment screw (a) and azimuth adjustment screw (b) so

that line "A" of the mirror tape runs in the center between

Lch and Rch in the reverse play mode.

2. After switching from REV to FWD then to REV, check that

the head position set in procedure "1" is not changed.

*If the position has shifted, adjust again and check.

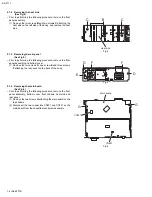

3. Adjust the azimuth screw (b) so that line "B" of the mirror

tape runs in the center between Lch and Rch in the forward

play

mode.

"Head Azimuth Adjustment"

1. Load the test tape ( VT724: 1kHz ) and play it back in the

reverse play mode. set the Rch output level to maximum.

2. Load the test tape ( VT703: 10kHz ) and play it back in the

forward play mode. Adjust the Rch and Lch output levels

to maximum, with azimuth adjustment screw (b).

In this case, the phase difference should be within 45°.

3. Engage the reverse mode and adjust the output level to

maximum, with azimuth adjustment screw (c).

*The phase difference should be 45° or more.

4. When switching between forward and reverse modes, the

difference between channels should be within 3dB.

*Between FWD Lch and Rch, REV Lch and Rch.

5. When the test tape ( VT721 : 315Hz ) is played back, the

level difference between channels should be within 1.5dB.

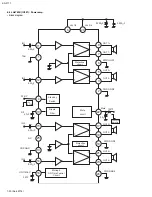

1. Check to see if the reading of the frequency counter & Wow

flutter meter is within 2940-3090 Hz ( FWD/REV ), and less

than 0.35% ( JIS RMS ).

2. In case of out of specification, adjust the motor with a built-

in volume resistor

1. Play the test tape ( VT724 : 1kHz ) back and set the volume

position at 2V.

2. Play the test tape ( VT739 ) back and confirm 0

±

3dB at 1kHz/

8kHz and -4+2dB at 1kHz/125Hz.

3. When 8kHz is out of specification, it will be necessary to

read adjust the azimuth.

Built-in

volume resistor

Tape Speed

2940-3090Hz

Wow&Flutter

Less than

0.35%

(JIS RMS)

Speaker out

1kHz/8kHz

: 0dB_}3dB,

125Hz/1kHz

: -4dB+2dB,

Summary of Contents for KS-F171

Page 23: ...KS F171 No 49774 1 23 ...