LX-D1010G

No. PA012

Feb.2000

COPYRIGHT © 2000 VICTOR COMPANY OF JAPAN, LTD.

LX-D1010G

CONTENTS

SPECIFICATIONS

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・

Table-2

SAFETY PRECAUTIONS

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

I

INSTRUCTION MANUAL

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

1. Field Service

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・

1-1

2. Packing Method

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

2-1

3. Before Disassembling

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

3-1

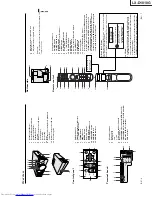

4. Removing Major Parts

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・

4-1

5. Hyper Terminal Setting Method

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・

5-1

6. Personal Computer Connection Method

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・

6-1

7. Circuit Adjustment Method

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・

・・・・・・・・・・・

・・・・・・・・・・・

・・・・・・・・・・・

7-1

8. About Hidden Commands

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・

・・・・・・・・・・・・

・・・・・・・・・・・・

・・・・・・・・・・・・

8-1

9. When replacement of the Main PWB Ass’y is necessary

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

9-1

10. Using the Warning Acquisition Software

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・

10-1

11. About Indicator Error Displays

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・

・・・・・・・

・・・・・・・

・・・・・・・

11-1

12. Entry

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・

・・・・・・

・・・・・・

・・・・・・

12-1

13. Lead Wire Wiring Diagram

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・

・・・・・・・・・・・

・・・・・・・・・・・

・・・・・・・・・・・

13-1

14. Connector Terminal Functions

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・

・・・・・・・

・・・・・・・

・・・・・・・

14-1

15. Block Diagrams

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

15-1

16. Overall Connection Diagrams

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・

16-1

PARTS LIST

・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・・・・・・

・・・・・・・・

・・・・・・・・

・・・・・・・・・

・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・

・・・

・・

・・

・・ ・・・

・・・

・・・

・・・

Parts-1

SERVICE MANUAL

LCD DATA PROJECTOR

Summary of Contents for LX-D1010G - Lcd Projector

Page 32: ...LX D1010G 4 10 PA012 Memo ...

Page 36: ...LX D1010G 6 2 PA012 Memo ...

Page 67: ... PA012 15 1 LX D1010G 15 BLOCK DIAGRAMS ...

Page 68: ... PA012 15 2 LX D1010G ...

Page 69: ...LX D1010G PA012 15 3 ...

Page 70: ...LX D1010G PA012 16 1 ...

Page 77: ...LX D1010G PA012 Parts 7 Memo ...

Page 81: ...しろページ ...