MX-G70

1-13

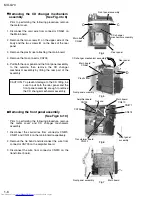

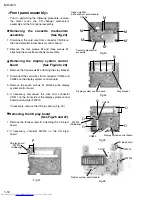

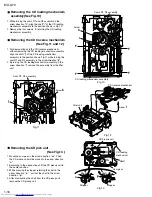

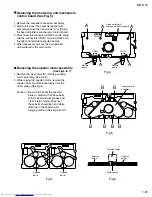

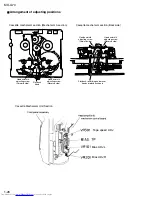

Prior to performing the following procedure, remove

the display system control board.

Pull out the preset knob on the front panel.

Remove the five screws

Q

attaching the preset /

tuning switch board.

1.

2.

Removing the preset / tuning switch

board (See Fig.28 and 29)

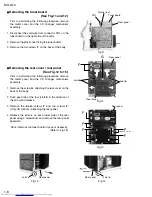

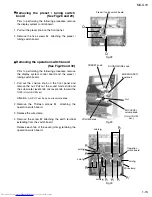

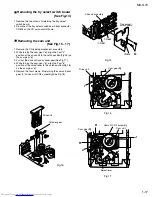

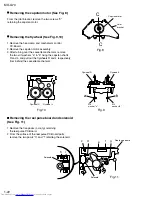

Prior to performing the following procedure, remove

the display system control board and the preset /

tuning switch board.

Pull out the volume knob on the front panel and

remove the nut. Pull out the sound mode knob and

the sub woofer level knob mic level knob toward the

front.

(Only US,UW ver.)

Attention:

A,UP,UY ver. have no mic volume knob

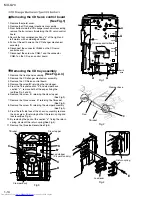

Remove the Thirteen screws

R

attaching the

operation switch board.

Release the wire clamp.

Remove the screw

R'

attaching the earth terminal

extending from the switch board.

Release each tab of the seven joints

g

retaining the

operation switch board.

1.

2.

3.

4.

Removing the operation switch board

(See Fig.29 and 30)

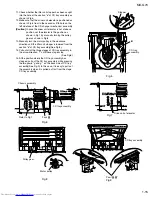

(Only US,UW

ver.)

Fig.28

Fig.29

Fig.30

Preset / tuning switch board

Q

Q

VOLUME knob

Nut

SUB WOOFER

level knob

SOUND MODE knob

PRESET knob

R

R

R'

R

R

R

R

R

Joint

g

Joint

g

Joint

g

Wire clamp

Joints

g

Joints

g

Operation

switch board

MIC LEVEL

volume knob