Mounting the Camera (Continued)

m

Process after connection

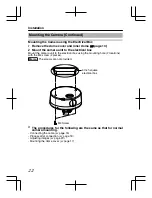

Fill the conduit hole and mounting holes with sealing agent and insert the silica

gel.

1

Fill the conduit hole and the screw mounted holes (2 locations)

with sealing agent (GE silicon)

Note

Seal the holes completely. Failure to do so may cause water or moisture

to enter, thereby fogging the lens and dome cover.

2

Remove the silica gel (provided) from its bag and insert in the

position as shown in the diagram

.

.

2

1

Silica gel

Lug plate

Sealing material

Silica gel insertion

space

This illustration is

for the purpose of

explanation.

The camera unit

is not shown here.

*

*

Secure the silica

gel with the lug

plate such that

it will not drop.

Note

v

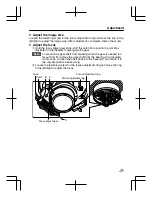

When mounting the camera under raining conditions, make sure that

rain does not enter into the camera.

v

Be sure to use the silica gel provided. Failure to do so may fog up the

camera lens and dome cover.

v

If you are not adjusting the camera angle soon after mounting the

camera, insert the silica gel (provided) only after adjustment.

Prolonged exposure to air will make the silica gel (provided) less

effective.

Installation

16