3-3

3.1.4 Jig connector cable connection

3.1.4.1 Preparation

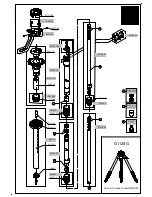

The Jig connector cable (YTU93106B) has been provided for

GR-DV2000 series. And it has been connected only 9 termi-

nals for low cost, although it has 30 terminals.

Now it can be used another series camcorder, but all the

terminals have to be connected by soldering wires. Refer to

the Service Bulletin (No. YA-SB-10082), and connect all the

terminals.

3.1.4.2 Connection

3.2 Mechanism compatibility adjustment

3.2.1 Tape pattern check

(1)

Play back the tape for compatibility adjustment.

(2)

Apply the external trigger signal to HID1, to observe the

waveform of the ENV_OUT.

(3)

Set to the manual tracking mode (ATF OFF).

(4)

Make sure that there is no significant level drop of the

waveform caused by the tracking operation, with its gen-

erally parallel and linear variation ensured. Perform the fol-

lowing adjustments when required.

(5)

Reduce the waveform by the tracking operation. If a drop

in level is found on the left side, turn the guide roller (sup-

ply side) to make the waveform linear.

If a drop in level is on the right side, likewise turn the guide

roller (take-up side) to make it linear.

(6)

Unload the cassette tape once, play back the tape again

and confirm that the waveform is flat.

(7)

Record at the recording tape, and play back the recorded

signal.

(8)

Confirm that the waveform is flat.

3.3 Electrical adjustment

Adjustment is performed by using personal computer. Read

README.TXT file to use the software for Service support sys-

tem properly.

As for the connection of cables, see Fig. Cable connection.

GUIDE ROLLER (TU)

GUIDE ROLLER (SUP)

TO JLIP_RX

TO JLIP_TX

TO GND

TO ENV_OUT

TO HID1

MENU

COMMUNICATION

CABLE

COMMUNICATION

CABLE

TO COMMUNICATION

CABLE

PC CABLE

SERVICE SUPPORT SYSTEM

RS232C

COM PORT

PERSONAL COMPUTER

JIG CONNECTOR

JIG

CONNECTOR

CABLE

TO JIG CONNECTOR

JIG CONNECTOR

RED

WHITE

BLACK

OSCILLOSCOPE

JIG CONNECTOR

JIG CONN.

MAIN CN105

PB_CLK

MAIN_VCO

HID1

FS_PLL

NC

NC

NC

MMOD_1

MMOD_0

JLIP_TX

MONI_CHG

EXMOD_1

IF_TX

I_MTR

GND

DISCRI

JLIP_RX

VCK

ENV_OUT

GND

CJIG_RST

AL_3VSYS

ATFI

VIDH

VPL

V_OUT

GND

VIDL

MON_G

MON_B

PB_CLK

MAIN_VCO

HID1

FS_PLL

DRST

SR

V_TX

TXD2

IF_TX

CJING_RST

JLIP_TX

MONI_CHG

VPPC

VPPD

AL_3VSYS

GND

DISCRI

JLIP_RX

RXD2

ENV_OUT

GND

REG_3V

SR

V_RX

ATFI

CVF_G

SP

A

V_OUT

GND

VIDL

MON_G

MON_B

A

B

C

PB_CLK

MAIN_VCO

HID1

FS_PLL

NC

NC

NC

MMOD_1

MMOD_0

JLIP_TX

MONI_CHG

EXMOD_1

IF_TX

I_MTR

GND

DISCRI

JLIP_RX

CVF_R

ENV_OUT

GND

CJIG_RST

AL_3VSYS

ATFI

CVF_G

CVF_B

V_OUT

GND

VIDL

MON_G

MON_B

A : Mega pixel with DSC model

B : Non Mega pixel with DSC model

C : Non Mega pixel without DSC model

Fig. 3-1-4-2b Schematic diagram of Jig CN

Fig. 3-1-4-2a Cable connection

ENV_OUT

HID1

Flatten the waveform.

Misalignment of guide roller

height on the take-up side

Misalignment of guide

roller height on the

supply side

Fig. 3-2-1a

Fig. 3-2-1b