3

CAUTION

Do not fix the side handle to the ring of the keyless

chuck because of a risk that doing so may damage

the ring.

6. Selecting the appropriate drill bit

䡬

When boring concrete or stone:

Use the drill bits for concrete.

䡬

When boring metal or plastic:

Use an ordinary metalworking drill bit.

䡬

When boring wood:

Use an ordinary woodworking drill bit.

However, when drilling 6.5 mm or smaller holes, use

a metalworking drill bit.

7. Selecting the driver bit

Screw heads or bits will be damaged unless a bit

appropriate for the screw diameter is employed to

drive in the screws.

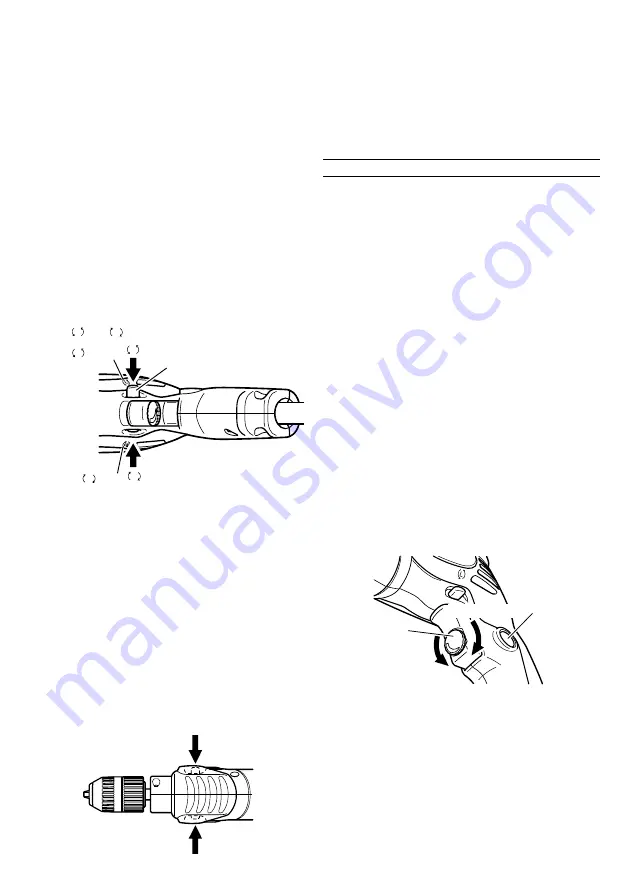

8. Check the rotational direction (Fig. 3)

The bit rotates clockwise (viewed from the rear side)

by pushing the R-side of the push button.

The L-side of the push button is pushed to turn the bit

counterclockwise.

(The

L

and

R

marks are provided on the body.)

Fig. 3

CAUTION

䡬

Never change the direction of bit rotation during

operation.

Turn the power switch OFF before changing the

direction of bit rotation; otherwise, the motor will

burn.

䡬

Always use with clockwise rotation, when using it

as an impact drill.

9. IMPACT to ROTATION changeover (Fig. 4)

The impact drill can be switched from IMPACT (impact

plus rotation) to ROTATION (rotation only) by simply

sliding the change lever. When boring concrete, stone,

tile or similar board materials, slide the change lever

right. The drill head impacts against the material

while continuing to rotate.

When boring metal, wood or plastic, slide the change

lever fully to the left. The drill simply rotates as an

ordinary electric drill.

Fig. 4

CAUTION

Do not use the impact drill in the IMPACT mode if the

material can be bored by rotation only. Such action

will not only reduce drill efficiency, but may also

damage the drill tip.

When changing over, ensure the change lever is slid

as far as it will go.

HOW TO USE

1. Pressure

Drilling will NOT be accelerated by placing heavy

pressure on the drill. Such action will only result in a

damaged drill bit, decreased drilling efficiency and/

or shortened service life of the drill.

2. Using a large diameter drill bit

The larger the drill bit diameter, the larger the reactive

force on your arm. Be careful not to lose control of

the drill because of this reactive force. To maintain

firm control, establish a good foothold, hold the drill

tightly with both hands, and ensure that the drill is

vertical to the material being drilled.

3. When drilling completely through the material

When the drill bit bores completely through the

material, careless handling often results in a broken,

drill bit or damage to the drill body itself due to the

sudden movement of the drill. Always be alert and

ready to release pushing force when drilling through

the material.

4. Switch operation

䡬

When the trigger is depressed, the tool rotates. When

the trigger is released, the tool stops.

䡬

The rotational speed of the drill can be controlled by

varying the amount that the trigger switch is pulled.

Speed is low when the trigger switch is pulled slightly

and increases as the trigger switch is pulled more.

䡬

The desired rotation speed can be pre-selected with

the speed control dial.

Turn the speed control dial clockwise for higher speed

and counterclockwise for lower speed (Fig. 5).

Fig. 5

䡬

Pulling the trigger and pushing the stopper, it keeps

the switched-on condition which is convenient for

continuous running. When switching off, the stopper

can be disconnected by pulling the trigger again.

CAUTION

Drill at a maximum rotation speed when drilling

wooden materials.

5. When driving wood screws

(1) Selecting a suitable driver bit

Employ plus-head screws, if possible, since the driver

bit easily slips off the heads of minus-head screws.

Impact

Rotation

Push button

L

mark

R

mark

R

L

Speed control dial

Stopper

Low speed

High speed

Summary of Contents for EDH550VRE

Page 7: ...6 ...