7

CAUTION

䡬

The dust cup and dust collector (B) are for exclusive

use of concrete drilling work. Do not use them for

wood or metal drilling work.

䡬

Insert dust collector (B) completely into the chuck

part of the main unit.

䡬

When turning the rotary hammer on while dust

collector (B) is detached from a concrete surface,

dust collector (B) will rotate together with the drill bit.

Make sure to turn on the switch after pressing the

dust cup on the concrete surface. (When using dust

collector (B) attached to a drill bit that has more than

190 mm of overall length, dust collector (B) cannot

touch the concrete surface and will rotate. Therefore

please use dust collector (B) by attaching to drill bits

which have 166 mm, 160 mm, and 110 mm overall

length.)

䡬

Dump particles after every two or three holes when

drilling.

䡬

Please replace the drill bit after removing dust

collector (B).

6. Selecting the driver bit

Screw heads or bits will be damaged unless a bit

appropriate for the screw diameter is employed to

drive in the screws.

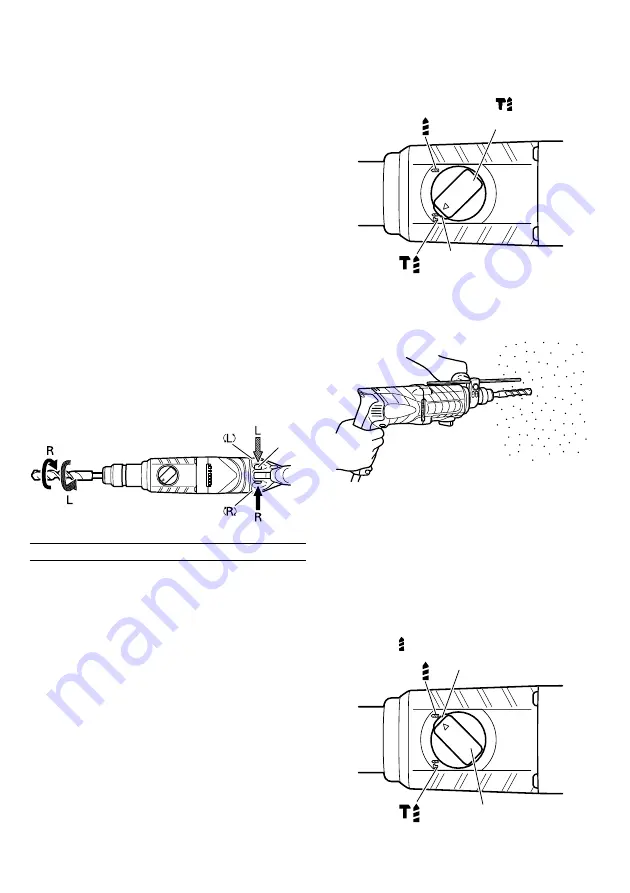

7. Confirm the direction of bit rotation (Fig. 5)

The bit rotates clockwise (viewed from the rear side)

by pushing the R-side of the push button.

The L-side of the push button is pushed to turn the bit

counterclockwise.

Fig. 5

HOW TO USE

CAUTION

To prevent accidents, make sure to turn the switch

off and disconnect the plug from the receptacle when

the drill pits and other various parts are installed or

removed. The power switch should also be turned

off during a work break and after work.

1. Switch operation

The rotation speed of the drill bit can be controlled

steplessly by varying the amount that the trigger

switch is pulled. Speed is low when the trigger switch

is pulled slightly and increases as the switch is pulled

more. Continuous operation may be attained by

pulling the trigger switch and depressing the stopper.

To turn the switch OFF, pull the trigger switch again

to disengage the stopper, and release the trigger

switch to its original position.

2. Ro hammering

This rotary hammer can be set to rotation and

hammering mode by pressing the push button and

turning the change lever to the

mark (Fig. 6).

Fig. 6

(1) Mount the drill bit.

(2) Pull the trigger switch after applying the drill bit tip to

the drilling position (Fig. 7).

Fig. 7

(3) Pushing the rotary hammer forcibly is not necessary

at all. Pushing slightly so that drill dust comes out

gradually is sufficient.

CAUTION

When the drill bit touches construction iron bar, the

bit will stop immediately and the rotary hammer will

react to revolve. Therefore grip the side handle and

handle tightly as shown in Fig. 7.

3. Rotation only

This rotary hammer can be set to rotation only mode

by pussing the push button and turning the change

lever to the mark (

Fig. 8).

Fig. 8

Push

button

Change lever

Push button

Change lever

Push button