8

To drill wood or metal material using the drill chuck

and chuck adapter (optional accessories), proceed as

follows.

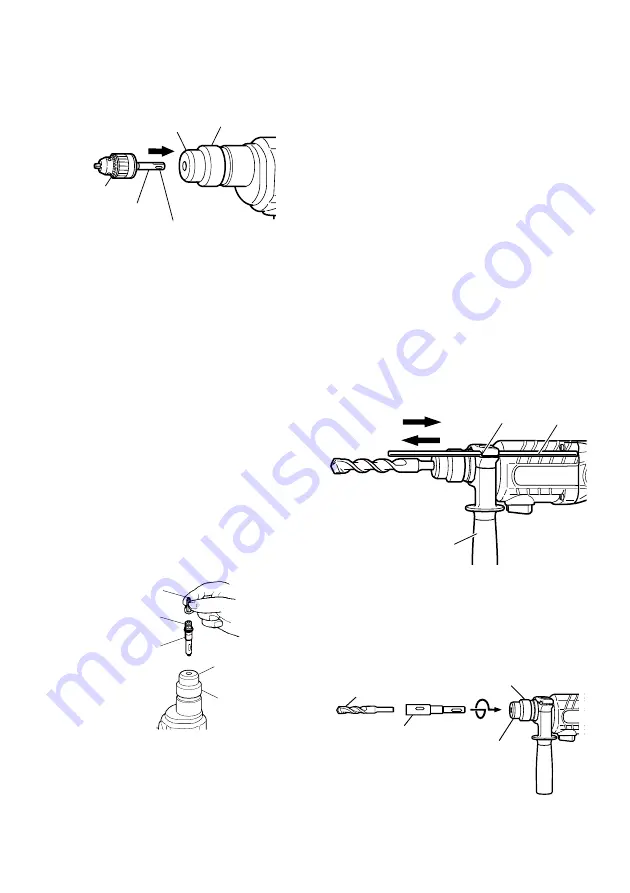

Installing drill chuck and chuck adapter: (Fig. 9)

Fig. 9

(1) Attach the drill chuck to the chuck adapter.

(2) The part of the SDS-plus shank is the same as the

drill bit. Therefore, refer to the item of “Mounting the

drill bit” for attaching it.

CAUTION

䡬

Application of force more than necessary will not

only expedite the work, but will deteriorate the tip

edge of the drill bit and reduce the service life of the

rotary hammer in addition.

䡬

Drill bits may snap off while withdrawing the rotary

hammer from the drilled hole. For withdrawing, it is

important to use a pushing motion.

䡬

Do not attempt to drill anchor holes or holes in

concrete with the machine set in the rotation only

function.

䡬

Do not attempt to use the rotary hammer in the

rotation and striking function with the drill chuck and

chuck adapter attached. This would seriously shorten

the service life of every component of the machine.

4. When driving machine screws (Fig. 10)

First, insert the bit into the socket in the end of chuck

adapter (D).

Next, mount chuck adapter (D) on the main unit

using procedures described in 4 (1), (2), (3), put the

tip of the bit in the slots in the head of the screw,

grasp the main unit and tighten the screw.

Fig. 10

CAUTION

䡬

Exercise care not to excessively prolong driving time,

otherwise, the screws may be damaged by excessive

force.

䡬

Apply the rotary hammer perpendicularly to the screw

head when driving the screw; otherwise, the screw

head or bit will be damaged, or driving force will not

be fully transferred to the screw.

䡬

Do not attempt to use the rotary hammer in the

rotation and striking function with the chuck adapter

and bit attached.

5. When driving wood screws (Fig. 10)

(1) Selecting a suitable driver bit

Employ plus-head screws, if possible, since the driver

bit easily slips off the heads of minus-head screws.

(2) Driving in wood screws

䡬

Prior to driving in wood screws, make pilot holes

suitable for them in the wooden board. Apply the bit

to the screw head grooves and gently drive the screws

into the holes.

䡬

After rotating the rotary hammer at low speed for a

while until the wood screw is partly driven into the

wood, squeeze the trigger more strongly to obtain

the optimum driving force.

CAUTION

Exercise care in preparing a pilot hole suitable for the

wood screw taking the hardness of the wood into

consideration. Should the hole be excessively small

or shallow, requiring much power to drive the screw

into it, the thread of the wood screw may sometimes

be damaged.

6. Using depth gauge (Fig. 11)

(1) Loosen the knob on the side handle, and insert the

depth gauge into the mounting hole on the side

handle.

(2) Adjust the depth gauge position according to the

depth of the hole and thighten the knob securely.

Fig. 11

7. How to use the drill bit (taper shank) and the taper

shank adapter

(1) Mount the taper shank adapter to the rotary hammer

(Fig. 12).

(2) Mount the drill bit (taper shank) to the taper shank

adapter (Fig. 12).

Fig. 12

Drill chuck

Chuck adapter

Part of SDS-plus shank

Front cap

Grip

Front cap

Chuck adapter (D)

Bit

Socket

Grip

Side handle

Depth gauge

Mounting hole

Drill bit

Front cap

Grip

Tape shank adapter