3

CAUTION

The sanding paper must be precisely installed on the

pad, ensuring that there is ample tension (leaving no

slack). Loosely installed sanding paper could result

in unevenly sanded surfaces and/or damage to the

sanding paper itself.

5. Attaching and Removing the Dust Bag

(1) Attaching the Dust Bag

As shown in Fig. 4, hold the dust gate and push it in

the direction of Arrow A to attach it to the dust outlet.

(2) Removing the Dust Bag

As shown in Fig. 4, hold the dust gate and pull it in

the direction of Arrow B to remove it from the dust

outlet.

CAUTION

Prior to the sanding operation, make sure the material

of surface you are going to sand.

If the surface under sanding operation is expected to

generate harmful / toxic dusts such as lead painted

surface, make sure the dust bag or appropriate dust

extraction system is connected with dust outlet tightly.

Wear the dust mask additionally, if available.

Do not inhale or touch the harmful / toxic dusts

generated in sanding operation, the dust can

endanger the health of yourself and bystanders.

PRACTICAL OPERATING PROCEDURES

CAUTION

Never apply water or grinding fluid when sanding.

This could result in electrical shock.

1. Switching the sander ON and OFF

The power can be turned on by setting the lever to

ON (1) and turned off by setting the lever to OFF (0).

CAUTION

Never turn the power switch ON when the sander is

contacting the surface to be sanded. This is necessary

to preclude damage to the material. The same applies

when switching the power OFF.

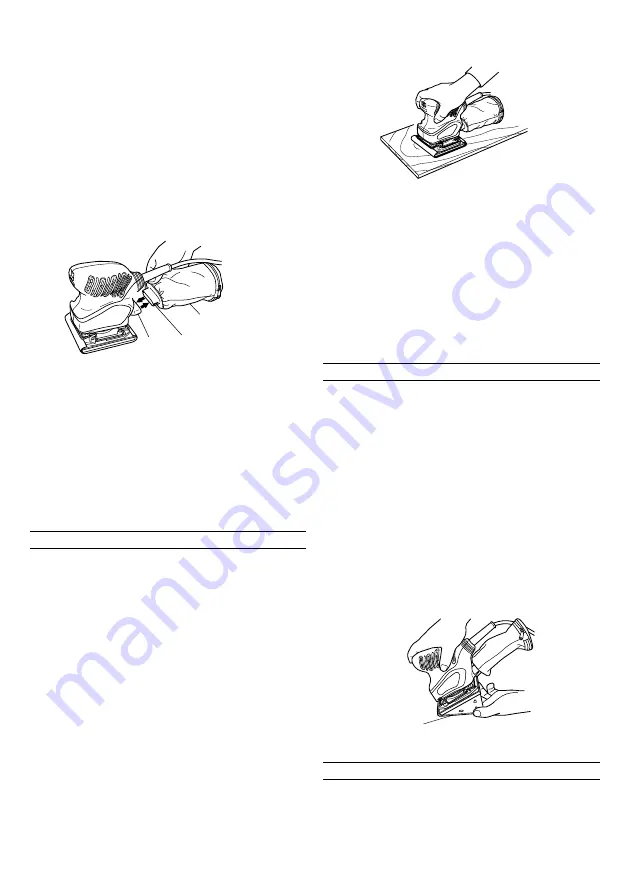

2. How to hold the orbital sander

While gripping the housing, lightly press the sander

against the surface to be sanded so that the sanding

paper uniformly contacts the surface, as shown in

Fig. 5. DO NOT apply excessive pressure to the sander

while sanding. Excessive-pressure may cause

overload of the motor, reduced service life of the

sanding paper, and lowered sanding or polishing

efficiency.

3. How to move the orbital sander

For optimum operating efficiency, alternately move

the sander forward and backward at a constant speed

and balance.

4. After installing new sanding paper

Movement of the sander may tend to become

unsteady after new sanding paper has been installed,

because of the new, coarse grain of the paper. This

can be avoided by slightly tilting the sander forward

or backward during sanding or polishing. Sander

movement will become steady as the sanding paper

surface becomes properly abraded.

MOUNTING THE OPTIONAL ACCESSORIES

1. Attaching a Sponge Pad (Velcro type) or a Stick-on

pad

Loosen the M4

×

10 screws (4) and remove the

attached pad. Next, attach a sponge pad (Velcro type)

or a stick-on pad.

CAUTION

Replace the pad only. Use the other parts without

removing them.

2. Attaching Velcro Type Sanding Paper or Stick-on

Type sanding Paper

Match the sanding paper’s hole with the pad’s hole

and strongly push the sanding paper with the palm

of your hand to fasten it securely in place.

3. Making a Hole in the Sanding Paper with the Punch

Plate (Fig. 6)

When using sanding paper without holes in it, punch

holes in it with the punch plate to improve dust

collecting capacity.

MAINTENANCE AND INSPECTION

1. Empting and cleaning the Dust Bag

If the dust bag contains too much saw dust, dust

collection will be affected. Empty the dust bag when

it gets full.

Remove the dust bag, open the fastener, and dispose

of the contents.

Fig. 4

Dust outlet

Dust gate

Dust bag

Fig. 5

Fig. 6

Punch plate

B

A

Summary of Contents for ESP110

Page 7: ...6 ...