2962P POWERFLEX SPEEDTILLER OPERATOR & SAFETY MANUAL

26

WARRANTY WILL BE VOIDED IF TILT OR

REAR ROLLER HYDRAULICS ARE FORCED

DOWNWARDS CAUSING ROLLERS TO

CARRY EXCESSIVE MACHINE WEIGHT

WHEN TURNING AND ON HEADLANDS.

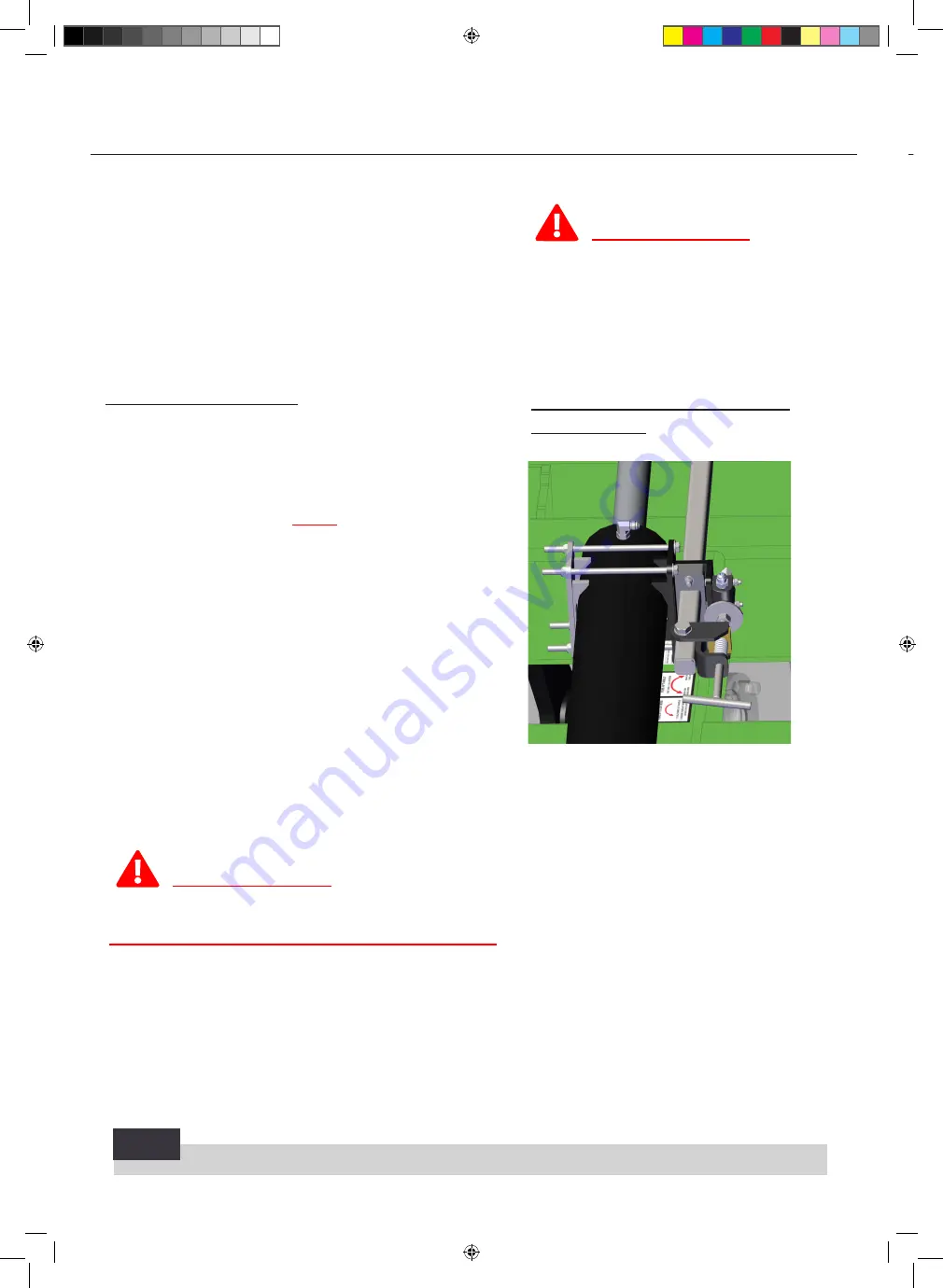

CONTROL BAR HYDRAULIC

VALVE STOP

WARNING

TIP*

When setting up machine, always start shallow, then

adjust down to required depth setting.

F I E L D O P E R A T I O N

Your Speedtiller Powerflex is a high performing speed

disc. You will need to become familiar with the settings

and adjustments to get the full benefit of your new

machine.

Front wheel hydraulics control the depth of cut for the

Powerflex giving more accurate depth control for hard

soils and heavy trash conditions for undulations such

as farm over contours etc. the roller hydraulics must be

placed in float mode.

MACHINE SETTINGS

• Rotate control bar hydraulic valve stop out to allow

tilt setting to be done on the go.

S

ee figure 31

• Remove and store all ram stops from rear rollers

(if fitted).

• Roller hydraulics (blue)

MUST

be placed in float

position.

• Operate wheel hydraulics (red) for setting depth.

• Operate tilt hydraulics (yellow) to set front to rear

depth ratio (tilt) and for best in line tracking.

S

ee tracking adjustments pg 30

• If machine pulls to the right; lower tilt. If machine

pulls to the left; raise tilt.

• Once front to rear depth ratio (tilt setting) is achieved,

• Rotate control handle to depress valve button and

maintain setting.

*NB

- Assure that all discs engage with the soil for

positive rotation. Where heavy trash conditions and loose soils

are encountered, machine may have to slew sideways slightly to

achieved desired result.

Figure 31 Valve stop

WARNING

NEVER REVERSE MACHINE WITH ROLLERS ON

GROUND.

2962P op & safety manual.indd 26

2962P op & safety manual.indd 26

21/03/2020 8:17:36 AM

21/03/2020 8:17:36 AM