2962P POWERFLEX SPEEDTILLER OPERATOR & SAFETY MANUAL

29

BEFORE STARTING WORK:

1. Follow tension specification on

Pg 19

before mounting wheel to

machine, check all hub and rim contact surfaces are

undamaged and free of paint, dirt and grease.

2. Check all pivot pins are fastened and anchor bolts are

correctly tensioned.

3. Lubricate wheel stubs with standard viscosity oil

4. Tension wheel nuts for torque specifications.

Pg 19

5. For field operation: Re-tension after 1st, 5th, then every 50

hours of operation.

6. For road travel re-tension first 3 miles (5kms), 10 miles

(15kms), and thereafter at 25 miles (40kms) intervals.

7. Check tires are inflated according to pressure stated on tire.

8. Check discs and disc bolt tension to specified torque

250ft/lb / 340nm.

9. Check for damaged, worn and fatigued parts. Have machine

repaired if necessary.

10. Ensure all appropriate safety decals are securely attached to

machine.

Pgs 13-18

11. Check hydraulic system is fully primed.

Pg 21

12. Check all safety mechanisms are in place and operating

correctly.

13. Lubricate rear roller bearings.

Pg 36

14. Instruction manual has been read, understood and stored

with machine.

Always reset adjustments after changing disc blades.

PERFORMING MAINTENANCE

DAILY MAINTENANCE CHECK FOR OPTIMUM PERFORMANCE

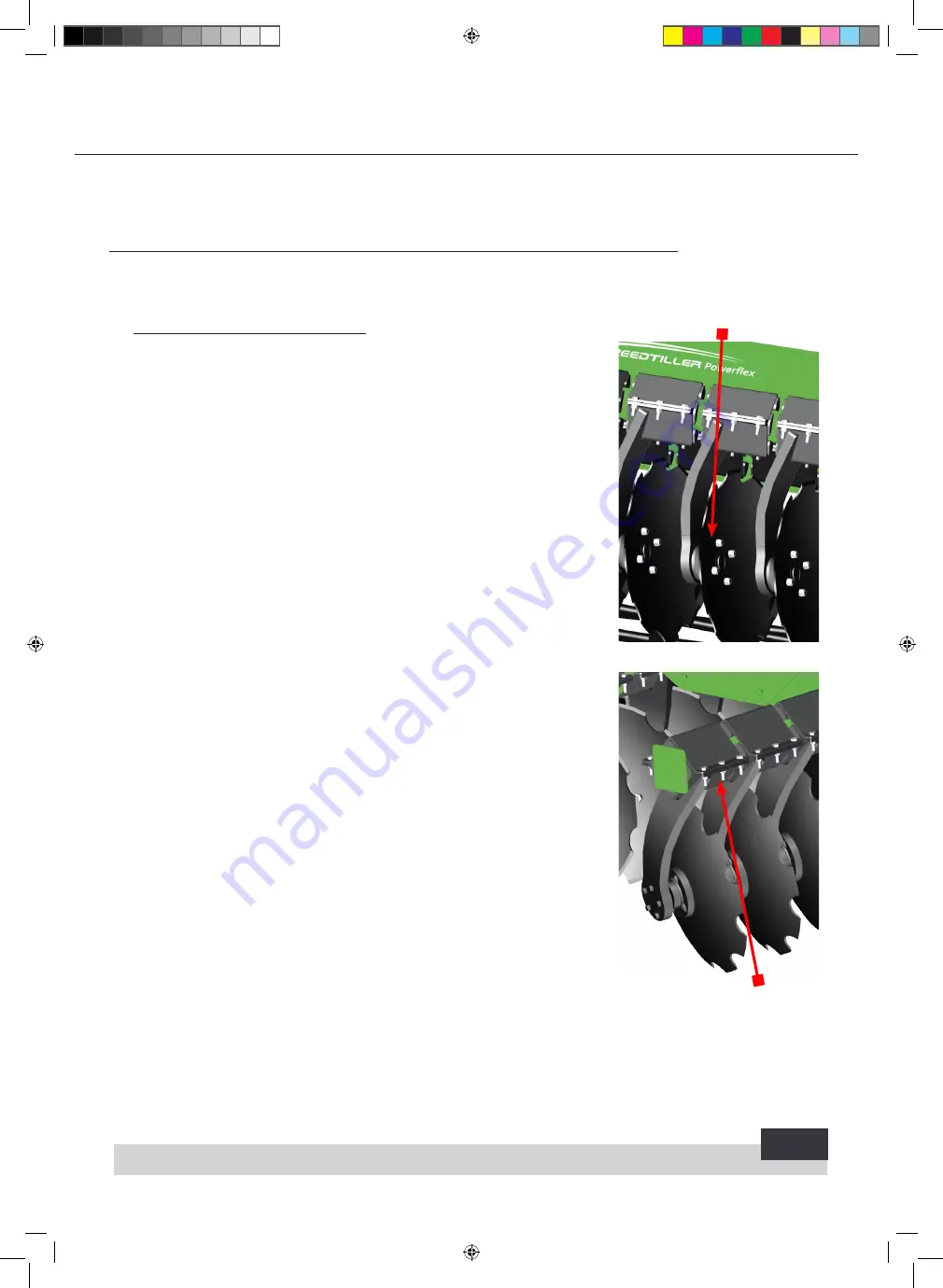

Disc arm locating bolts -

Check first 10hrs of operation

Disc bolts -

Check first 10hrs of operation

Figure 33

Figure 32

2962P op & safety manual.indd 29

2962P op & safety manual.indd 29

21/03/2020 8:17:36 AM

21/03/2020 8:17:36 AM