Instruction Manual

Section Five

for best results. The main factors to be considered are the material being ground,

size of work, amount of stock to be removed, and the finish desired. The harder

the material, the softer the wheel required. The larger the work diameter, the

coarser and softer the wheel. The amount of stock removal and the finish will

determine the grain size economical for the job. Light feed of the material to the

wheel permits the use of finer and softer wheels.

For sharpening Fellows Gear Shaper cutters, slightly finer grit wheels, approximately

80 grit, should be used. A complete list of wheels to use for sharpening various

types of cutters is not included, as many handbooks listing complete grinding wheel

recommendations are available from the manufacturer.

Dry grinding is generally recommended for most high-speed steel cutter sharpening

operations because experience has shown that satisfactory results are readily obtained

in this way, and the operations

are

such that wet grinding causes inconvenience to

the operator. When wet grinding, use sufficient supply of coolant to keep the work

from overheating. In wet cylindrical grinding, slightly harder wheels may be used.

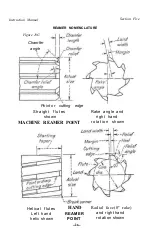

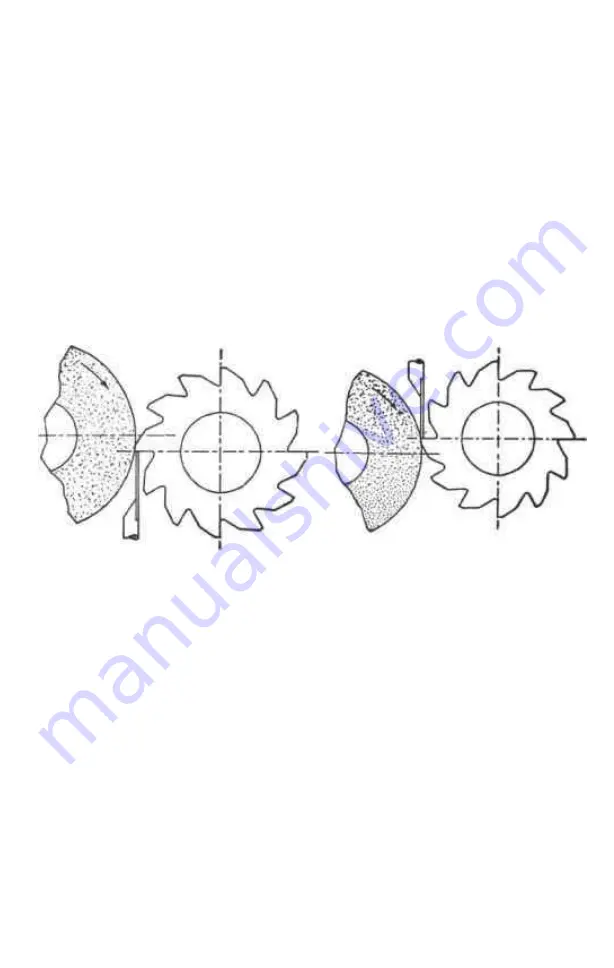

Figure 11

—

Showing method of grind- Figure 12

—

Showing method of grinding

ing with wheel rotating off cutting edge. with wheel rotating onto cutting edge.

II. DIRECTION OF WHEEL ROTATION

Cutters and reamers may be ground with the grinding wheel rotation either off or

toward the cutting edge as shown in Figures 11 and 12.

If the wheel is run off or away from the cutting edge as shown in Figure 11, the wheel

holds the cutter against the toothrest As this is the safer method, it is more com-

monly used. This setup may be reversed, if so desired, cutting edge facing up,

toothrest pointing down, and wheel running counterclockwise. It has the objection,

however, of throwing up a burr on the cutting edge of the tooth which should be

oilstoned off. Furthermore, there is some danger of burning the tooth at the cutting

edge.

If the cutter is ground by rotating the wheel onto the cutting edge as shown in

Figure 12, there is less tendency to burn the tooth, and a keener cutting edge, free

from burr, is possible. Care must be taken, however, to hold the cutter firmly

against the toothrest, as otherwise the rotation of the wheel will carry the tooth

into the wheel and cause it to be ground away

While straight wheels are shown in Figures 11 and 12, the same comments regard

ing direction of grinding wheel rotation apply to the use of cup wheels.

- 2 2 -