Instruction Manual

Section Five

bearing from front to rear. If teeth lands show a taper, make small

adjustments on the table swivel.

10. After the teeth appear sharp, loosen the workhead vertical swivel and

adjust the workhead tilt to the desired secondary clearance angle, then

lock. Grind the secondary clearance as in (9) above until each tooth has

a primary land of no more than

1

/

16

inch in width.

I I . If it is desirable to grind a heel on the face of the mill, reset the work

head to the primary clearance angle tilt, swivel the workhead in the hori

zontal plane to a setting of 87 degrees, lock, and grind the face on all

teeth until the length of the primary is no longer than about

⅛

inch.

12. If the end mill is too long so that when installed in the conventional

workhead it does not permit room between its end and the wheel, the

swivel table on the grinder may be moved off its bed rests at its ends

and swiveled to some convenient angle which allows the workhead to clear

the

wheel

sufficiently. Simply set this angle used on the swivel table as

a correction factor on the horizontal swivel of the workhead.

B

Using a Tilthead Grinder:

Repeat all steps in IV-A above as necessary, only wherever the instructions

call for tilting the workhead, instead tilt the Wheelhead for the desired pri

mary or secondary clearance, leaving the workhead set at 0 degrees in the

vertical plane. Note the tilting Wheelhead in Photo 24.

CHAPTER 5

Straight Tooth Side Milling Cutter

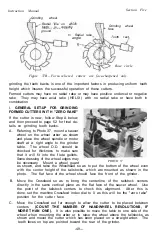

I. SET-UP PREPARATION FOR PERIPHERY

Refer to Chapter 3-1, page 36 for initial instructions on position of the cutter, how

it is held, the wheel used, etc. If the cutter teeth have no helix, the toothrest

should be mounted on the table for fastest indexing of teeth across the wheel.

Each tooth is held firmly against the toothrest blade and each ground in succession,

using the same principles described in Chapter 3 and Chapter 4

II. SET-UP FOR CLEARANCE ANCLE

AND THE SHARPENING PROCESS

Refer to Chapter 3 for information on

clearance angles when the toothrest is

mounted on the Wheelhead. When the

toothrest is mounted on the table, place

a tooth on the toothrest blade and then

place the end of the blade at the same

center height with the center of the cutter

by using height gauge. Rotate cutter tooth

downwards by means of the micrometer

adjustment to create necessary clearance

Engage cutter with wheel and sharpen as

described in Chapter 3. See Photo 27

PHOTO

27

I I I . SET-UP FOR SHARPENING THE SIDE TEETH

The set-up is similar to that of grinding the face (teeth ends) of a shell end mill

(SEE CHAPTER 3). Place the cutter in a universal workhead. Sides of the teeth

should be ground with at least .001 inch back taper on the primary clearance so

that the teeth are larger at the periphery of the cutter. Repeat this process for

both sides of the cutter.

-40-