Instruction Manual

Section Five

grees toward the cutter center; with a chamfer of 60 degrees from parallel with

the axis of cutter, with simulated peripheral cutting edges; all cutting edges having

only one relief angle of 5 degrees ( for chamfer and face). Instructions are for

non-tilthead grinders unless otherwise noted.

I. SHARPENING THE CUTTER FACE

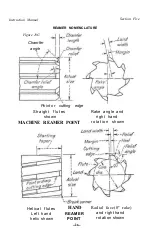

PHOTO 32

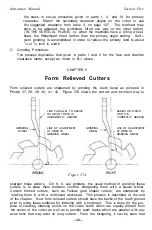

PHOTO 33

A. Set-up Preparation;

Place a diamond flared cup wheel or other suitable wheel on the wheel

collet or mounting arbor and attach it to the spindle. Select the proper

wheel speed by use of the correct pulleys and belt Place the axis of the

wheel at a 90-degree angle (OR AT AN 89-DECREE ANCLE IF CLEAR

ANCE IS NEEDED ON OPPOSITE SIDE OF WHEEL) to the table travel

of the machine and with the use of the height gauge, place the wheel cen

ter at the same height as the workhead center (centers of tailstocks may

be used as a gauge for the height of the workhead).

Place large, sensitive workhead at the far right of the swivel table with

its base about 3 inches in from the end Align the workhead base with

the table T-slot by tightening the base plate clamp bar assembly to the

outer edge of the table with the hex socket screw. Tighten the two base

plate T-slot bolts. Turn the correct workhead spindle taper toward the

rear of the machine 'see Photo 32) by loosening the swivel stud nut on

its base and rotating the workhead until the index mark lies at 90 degrees,

Tighten the swivel stud nut Loosen the upper swivel nut on the work

head, tilt the workhead up or down to obtain the desired primary clear

ance angle back of the cutter faces (5 degrees in this instance), and

tighten the upper swivel.

NOTE:

The B992 workhead must be tilted up

ward on all machines; the B9092 may be tilted either up or down. (See

photo 33).

Place the cutter with its milling machine arbor in the workhead and tighten

the draw-bolt assembly. Care must be taken to keep taper surfaces clean

and un-nicked Loosen the clamp bar holding the swivel table at the right

side of the machine and use the table adjusting screw to advance the table

inward at the right so that the pointer at the left side of the table shows

2 degrees. If may be necessary to loosen slightly the center swivel fric

tion locking screw of this fable Tighten the clamp bar.

- 4 4 —