Instruction Manual

Section Five

Grinding wheel

Grinding wheel

face

Base circle

Figure 37B

—

Form-relieved cutters are face-sharpened only.

grinding the teeth backs is one of the important factors in producing uniform tooth

height which insures the successful operation of these cutters.

Formed cutters may have no radial rake or may have positive undercut or negative

rake. They may have axial rake (HELIX) with no radial rake or have both in

combination.

I.

GENERAL SET-UP FOR GRINDING

FORMED CUTTERS WITH "ZERO RAKE"

If the cutter is new, follow Step A below,

and then proceed to page 52 for final de

tails on grinding teeth backs.

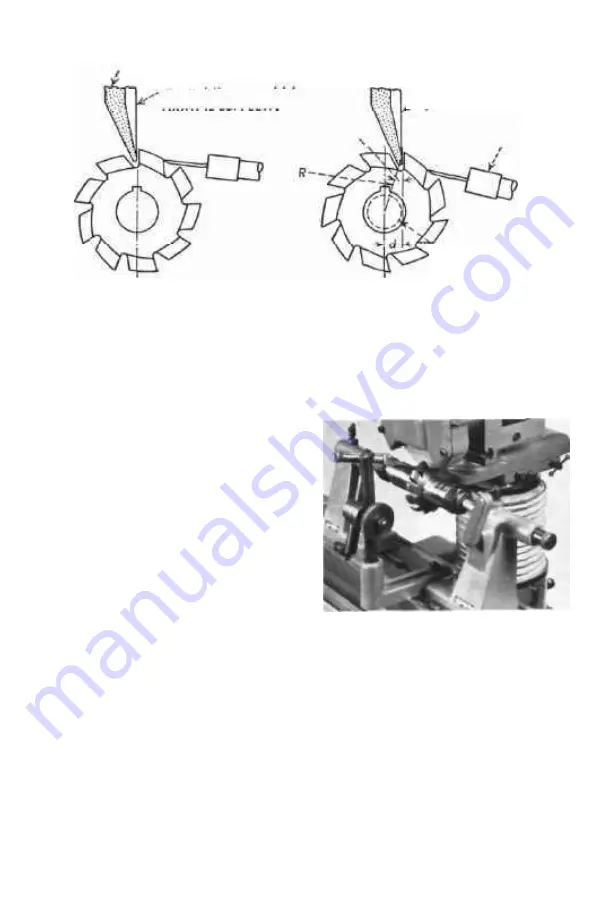

A. Referring to Photo 37, mount a saucer

wheel on the wheel arbor as shown

and place the wheel spindle or motor

shaft at a right angle to the grinder

table. The wheel O.D. should be

checked for thickness to make sure

that it will fit into the flute gullets.

Some dressing of the wheel edges may

be necessary. Mount a wheel guard

as shown, and raise the Wheelhead so as to put the bottom of the wheel even

with the center height of the tailstocks, which are mounted as shown in the

photo. The flat face of the wheel should face the front of the grinder.

B. Move the Crossfeed so as to bring the centerline of the tailstock centers

directly in the same vertical plane as the flat face of the saucer wheel. Use

the point of the tailstock centers to check this alignment. After this is

done, set the machine Crossfeed index dial to 0. as this will be the "zero rake"

position for the cutter face.

C. Move the Crossfeed out far enough to allow the cutter to be placed between

centers

(COUNT THE NUMBER OF HANDWHEEL REVOLUTIONS, IF

MORE THAN ONE).

It is also possible to move the table to one side of the

wheel when mounting the arbor or to raise the wheel above the tailstocks as

shown and mount the cutter which has been placed on a straight arbor. The

teeth faces on top are pointed toward the rear of the grinder.

PHOTO 37

-49—

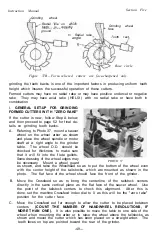

Radial line on which

tooth is correctly

ground

r=

Radial rake

angle

Tooth rest.