Instruction Manual.

Section Five

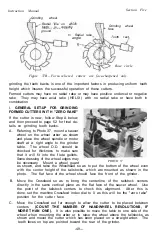

7. Begin to form the wheel with the diamond by advancing the machine

Crossfeed while swinging the fixture through a predetermined arc. It will

often be possible to measure the amount of total infeed of the nib into

the wheel by means of the machine Crossfeed dial. Measure the amount

of the radius after the point strikes the wheel

(FOR A CONCAVE RADIUS),

or after the Gauge edge contacts the wheel

(FOR A CONVEX RADIUS).

8. If the convex radius is to be tangent to the side and periphery, it will

be necessary to measure the radius distance in from the wheel side and

set the grinder table stops.

9. If optical observation is involved, no measuring of Crossfeed on the ma

chine will be necessary as infeed into the wheel will take place until the

formed radius conforms to the template on the observation scope.

B. Radius work on the corners of face mills up to approximately 10 inches diam

eter can be accomplished on the radial grinding fixture with the addition of

the B992 Workhead mounted on the fixture Upper Slide. This workhead,

having a standard taper of 50MM, may be adapted to 40MM taper or to

B & S No. 11 taper.

C. Form tools and chip breakers can be held by the B989 Universal Workholding

Fixture which can be mounted on the radial fixture Upper Slide.

- 6 3 -