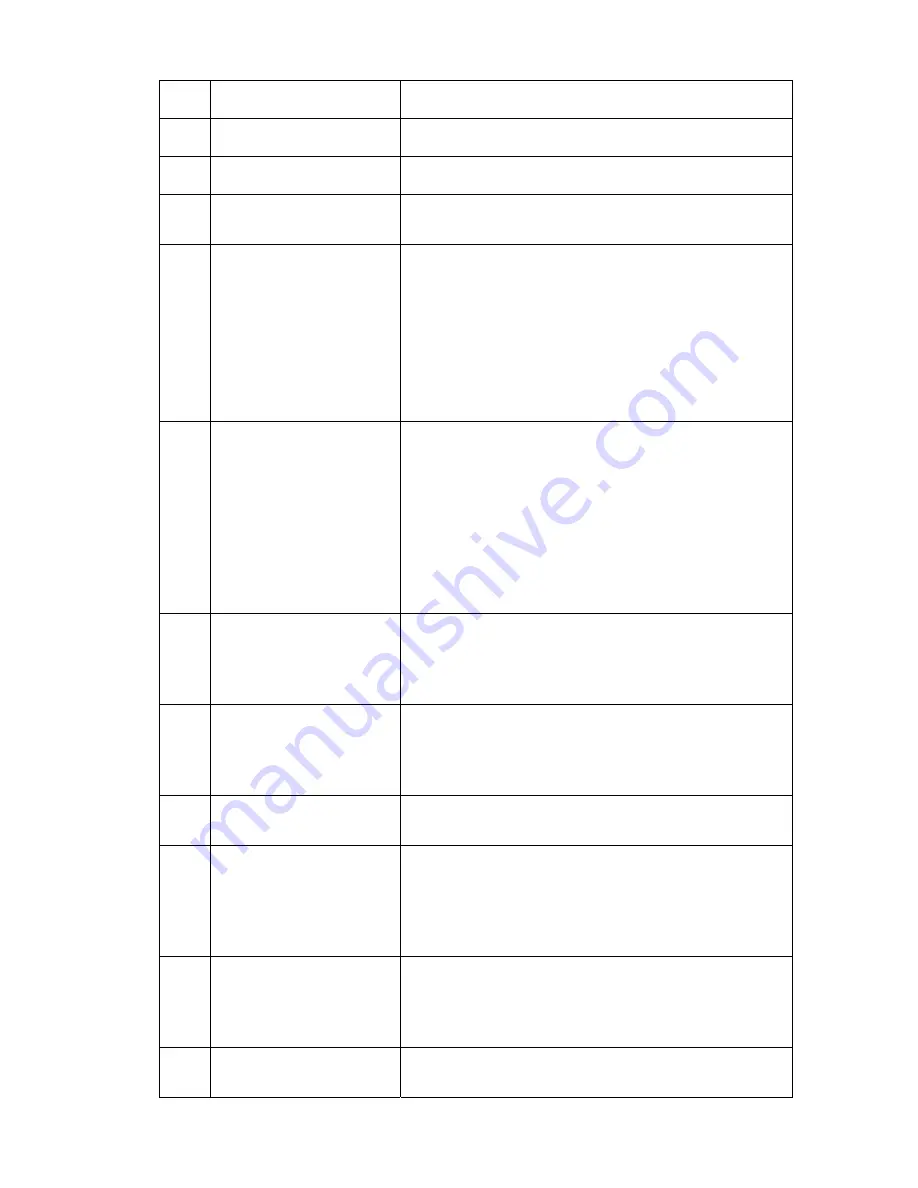

15

32 Belt Tension Bar

Adjust tension of the timing belt.

33 Lower Transmit Shaft

Link timing pulley to drive lower feed roller.

34 Conductive Brass Ring A Brass ring for electric conduction.

35 Timing

Pulley

A component of transmission mechanisms which

conveys the lower motor’s power to tooling horn.

36 Adjusting

Bolt

These bolts adjust the height and horizontal plane

of the horn surface.

Caution:

It is very important not to alter the

setting of the horizontal plane of the horn

surface.

This should match the exact axis of the working

roller and should only be performed by a trained

technician or engineer.

37 Paper

Tape

It supplies the paper strip especially in cutting

cloth. Usually the paper strip must fit under the

workpiece and prevent direct contact between the

running horn and cutting roller, and helps to

prevent scratches on the horn surface. Also, it

prevents the melting materials from sticking on

the horn surface. And most importantly, when

cutting cloth, it acts as a cushion to the horn

surface and makes cutting cloth easier.

38 Paper Tension Bar

This is the mechanism which applies tension to

the paper strip and keeps it straight while paper

tape is passing through the working roller then to

the puller roller.

39 Paper Strip Guide

Guides the paper strip that is below the

workpiece

(used especially in cutting cloth) and in

transporting material to the puller roller.

40 O.P.P. Tape Guide

Used to guide the O.P.P. strip into the working

positions.

41 O.P.P.

Tape

The O.P.P. tape is used on top of the workpiece

and as well as helping in the transportation of the

material through the machine, makes the removal

of cuttings from the material much easier and

cleaner.

42 Pressure Adjusting Bolt

The setting of pressure depends on whether the

workpiece is carried out smoothly or not. On

some materials it may prevent creases if

tightened.

43 Fixed

Nut

It is for locking the pressure adjusting bolt to

prevent the bolt from moving while working.

Summary of Contents for KS-2010

Page 12: ...11 ...

Page 13: ...12 ...

Page 22: ...21 ...

Page 23: ...22 ...

Page 31: ...30 6 4 Wiring Diagram A MAIN WIRING DIAGRAM A 1 KS 72 ...

Page 32: ...31 A 2 KS 85 ...

Page 38: ...37 FUSE FUSE B GENERATOR CIRCUIT DIAGRAM KS 72 KS 85 KS 2010 KS 3010 ...