44

7.5 Installation and Replace the Working Roller

A.

Tread down the left side foot switch to lift up

the sealing roller bracket.

B.

Remove the outer W.R. bracket by loosing the 2 set screws with the T-type

hexagon wrench supplied. Then take out the roller. When installation the

desired working roller, be sure that the hole in the working roller fits into the

pin on the pulley wheel gear. And the long shaft innermost towards the inner

side.

C.

Using 2 screws install the outer working roller bracket, then tread down the left

side foot switch again to lower down the roller bracket.

D.

Feed the workpiece in between O.P.P. strip and paper strip and run the machine.

E.

Adjustment: If the workpiece is not uniform across the width (i.e. more

pressure is applied one side than the other), then adjust the height of outer

bracket

(

loosen the screws

)

and raise or lower the outer bracket to suit

(retighten the screws) the retest.

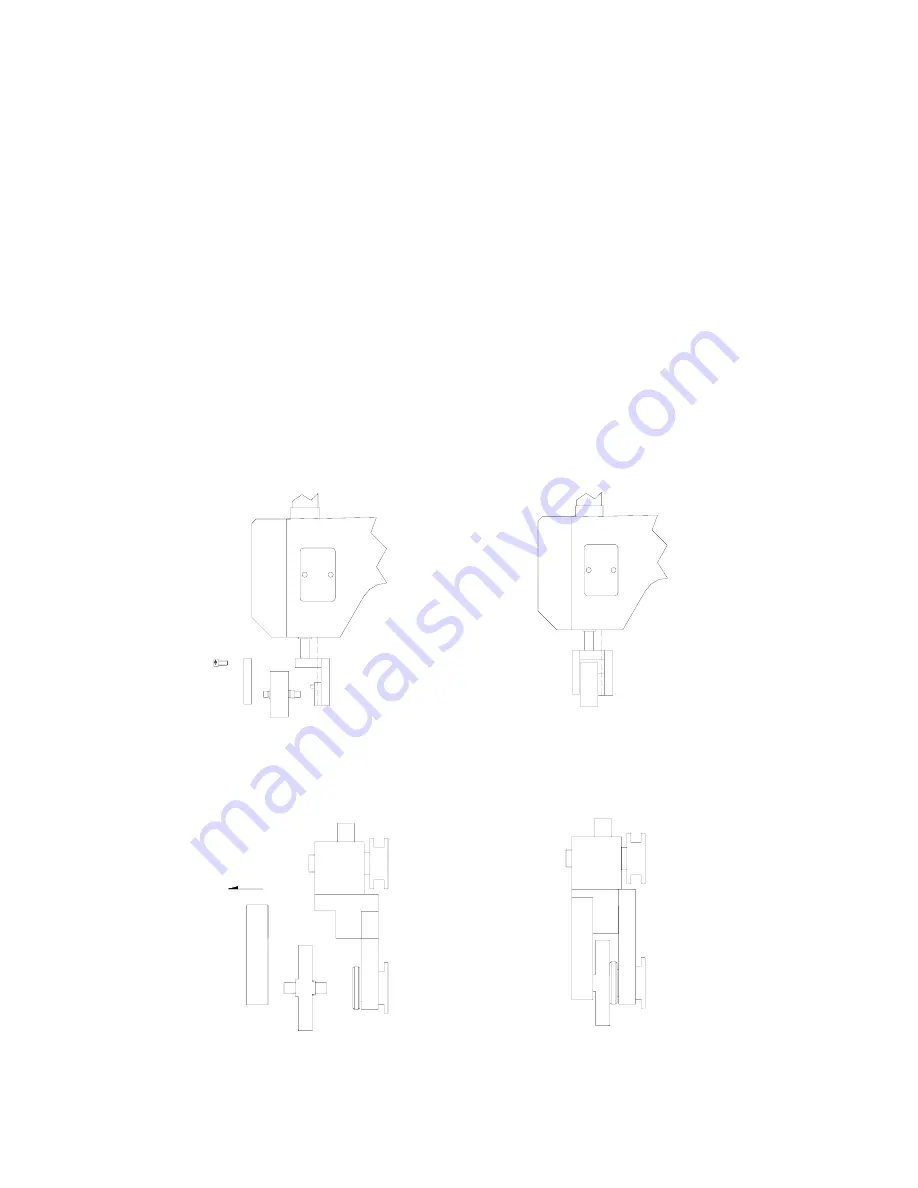

(KS-72, KS-85 Fig. 1) (KS-72, KS-85 Fig. 2)

(KS-2010, KS-3010 Fig. 1) (KS-2010, KS-3010 Fig. 2)

Summary of Contents for KS-2010

Page 12: ...11 ...

Page 13: ...12 ...

Page 22: ...21 ...

Page 23: ...22 ...

Page 31: ...30 6 4 Wiring Diagram A MAIN WIRING DIAGRAM A 1 KS 72 ...

Page 32: ...31 A 2 KS 85 ...

Page 38: ...37 FUSE FUSE B GENERATOR CIRCUIT DIAGRAM KS 72 KS 85 KS 2010 KS 3010 ...