KTI63505 3 9/12/17

INSPECTION AND SETUP INSTRUCTIONS

Visual inspection should be made before each use of the transmission jack, checking for leaking hydraulic fluid and damaged,

loose or missing parts. Each jack must be inspected by a manufacturer’s repair facility immediately if accidentally subjected to an

abnormal load or shock. Any jack which appears to be damaged in any way, found to be badly worn, or operates abnormally MUST

BE REMOVED FROM SERVICE until necessary repairs are made by a manufacturer’s authorized repair facility. It is recommended that

an annual in spec tion of the jack be made by a manufacturer’s authorized repair facility and that any defective parts, decals or warning

labels be replaced with manufacturer’s specified parts. A list of authorized repair facilities is available from the manufacturer.

Refer to parts breakdown on page 6 and 7:

1. Before using jack for the first time, some assembly is required. Place hydraulic unit in upright position and bolt legs (#R30) to base

(#R38) using bolts (#R34) and washers (#R32 and R33).

2. Assemble each caster to leg using washers (#R36) and nuts (#R35).

3. Attach fingers (#2) to plate (#3) using bolts (#1), washers (#4), and wing nuts (#5).

AIR BLEEDING INSTRUCTIONS

IMPORTANT!

If the transmission jack is not able to raise the load, or raises it very slowly, there may be air trapped in the hydraulic

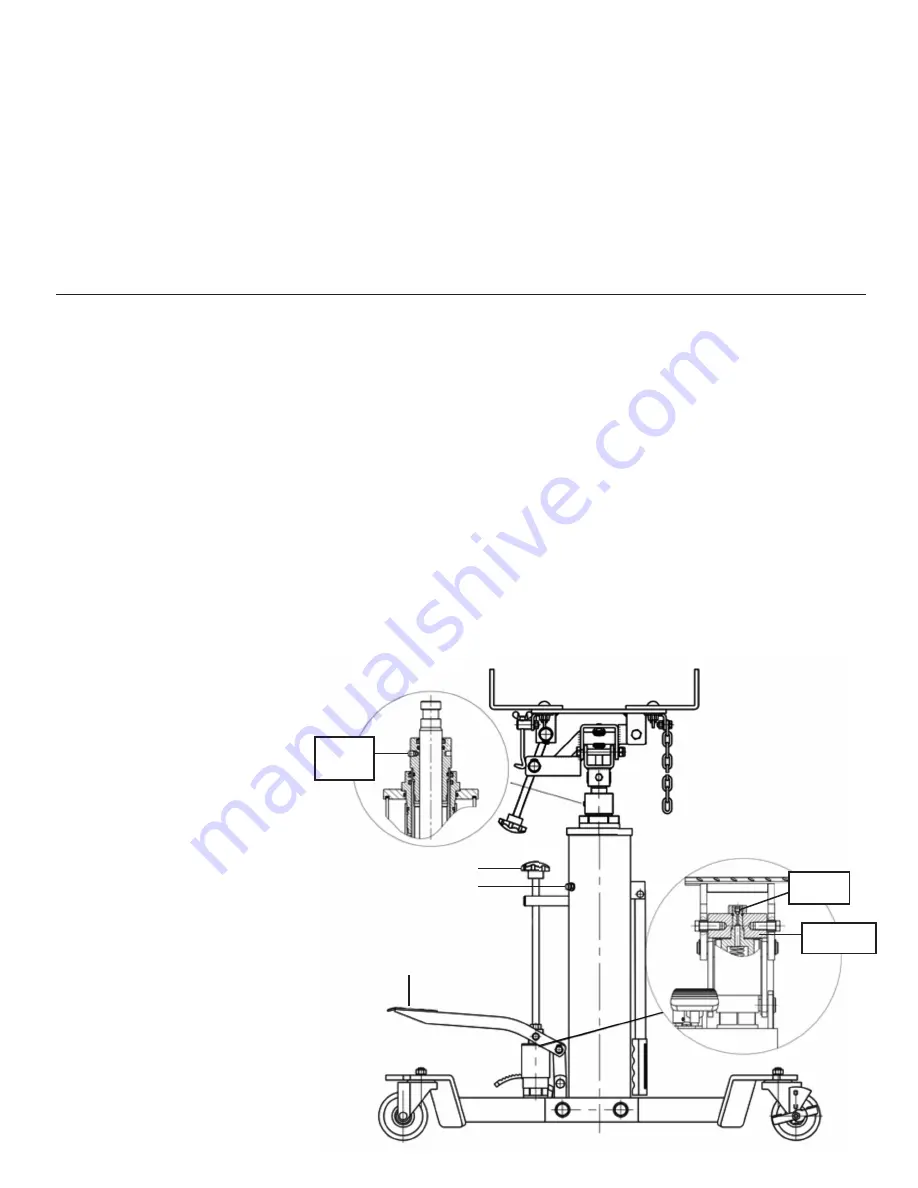

system. Follow these instructions and refer to Diagram 1 and parts page 7:

1. Turn the air vent screw (#R23) counterclockwise until it stops.

2. With both rams in their lowered position, turn the release knob (#R50) clockwise until it stops.

3. Loosen but do not remove the M6 x 5 inner Allen socket screw (#R52) by turning it counterclockwise two revolutions.

4. Pump the foot pedal (#R44) 2 or 3 times until you see oil coming out of the M6 x 5 Allen socket screw hole.

5. After 3 foot pumps, hold the pedal (#R44) down while simultaneously turning the M6 x 5 Allen socket screw (#R52) clockwise

until tight.

6. Activate the pedal (#R44) to see if the jack can raise smoothly. If not, repeat steps #2 through #5 again.

If the transmission jack can raise a load but its rams are not traveling smoothly, there may be air trapped in the rams that need to be

bled as follows:

1. Turn the release valve knob (#R50) clockwise until it stops. Activate the foot pedal (#R44) until both rams are fully extended.

2. Turn the M8 x 10 BLEED SCREW (#R14) counterclockwise 1 to 1.5 revolutions, pump the foot pedal (#R44) 2 to 3 times until oil

comes out of the M8 x 10 BLEED SCREW hole.

3. Turn the M8 x 10 BLEED SCREW (#R14) clockwise until tight.

4. Turn the release valve knob (#R50) in a counterclockwise

direction to lower both rams all the way down. Turn

the release valve knob (#R50) clockwise until it

stops and pump the jack to maximum height.

Operate the jack up and down

once again to see if the rams

are responding properly. If better

but not complete, repeat steps

#1 through #4 again.

M6 x 5

SCREW

M8 x 10

BLEED

SCREW

DIAGRAM 1

R50

R23

BLOCK

OF STEEL

R44